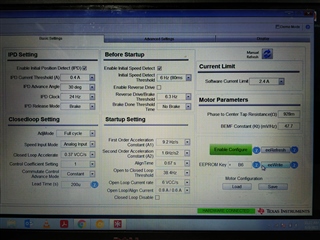

Other Parts Discussed in Thread: DRV10983, DRV10987

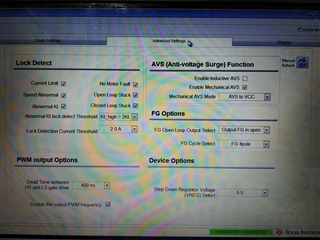

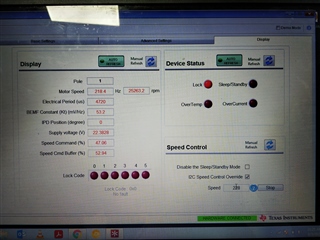

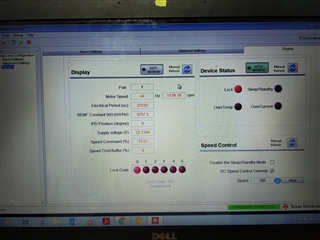

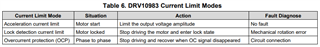

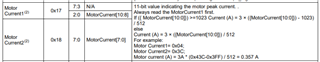

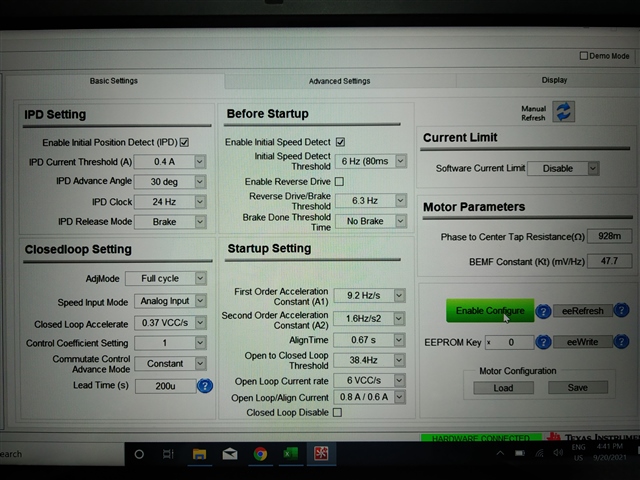

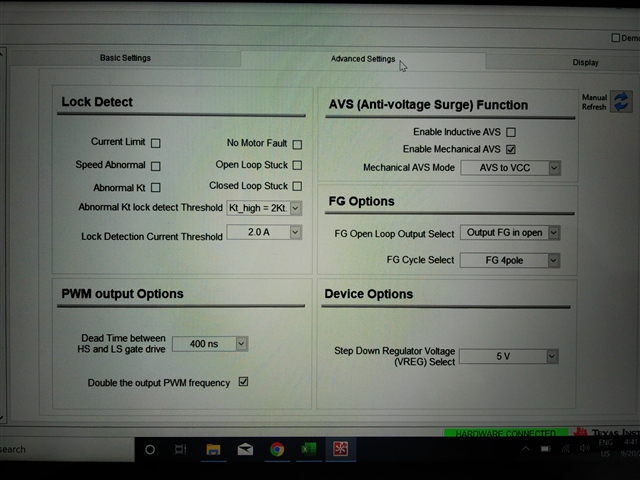

We are using a DRV10983 IC for driving a Maxxon ECX SQUARE 16 L sensorless brushless BLDC motor, but when we try to run it with all the motor-lock safety checks enabled and a stall condition is introduced, the motor switches off as expected but once the stall torque is removed and the motor switches back on, the motor - driver keeps detecting lock condition and switches off intermittently. Is this normal? how can we avoid this?