Hi team,

After DRV2624YFFR motor drive is calibrated at F0, some watches will vibrate after hard restart of the watch.

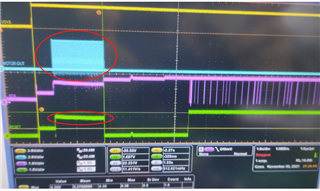

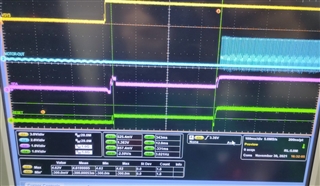

From the quantitative waveform, I2C has no communication, and the chip is not fully up, the motor vibrates by itself.

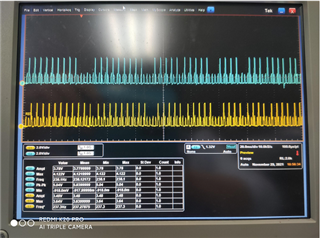

This problem related to the motor were discovered during the mass production process. After the TI chip is calibrated, it is found that the motor has regular vibration and short-term vibration when it is turned on. The normal state should be no vibration.

Phenomenon 1: Before the motor is calibrated, the driver IC of AW vibrates when it is turned on, and the driver IC of TI not vibrates when it is turned on.

Phenomenon 2: After the motor is calibrated, AW did not find any vibration when starting up. TI has found that 7pcs machines must vibrate when starting up, and some are long vibrations and some are short vibrations.

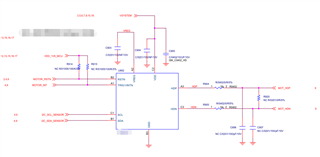

The figure below shows the vibration waveform and the waveform of the flying wire of the motor shrapnel when the machine is turned on.

The customer would like to know what's the possible reason for the vibration. Could you help check this case?

Thanks and Best Regards,

Cherry