Other Parts Discussed in Thread: DRV8830, DRV8832

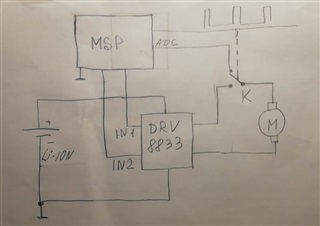

Hello. I am using DRV8833 for low voltage motor. In my circuit, I only use the reverse. I don't use PWM. Now I have a question about keeping the engine speed constant. It's like old cassette recorders. It used an electronic circuit of constant revolutions. Are there similar microcircuits in the catalog. Importantly, it is powered by a 4 volt lithium battery. There is a very old chip TDA7274. Perhaps there is something modern at TI.