Other Parts Discussed in Thread: DRV8244S-Q1LEVM, DRV8243-Q1

Hi, TI expert.

The customer referred to the EVM board (DRV8244S-Q1LEVM) and applied DRV8244-Q1 (DRV8244SQRYJRQ1) to configure the controller to control the seat of the electric car's leg.

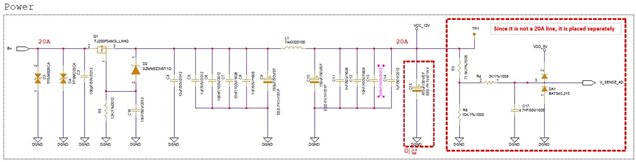

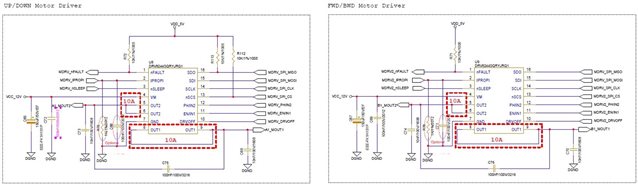

The circuit below is the power part and motor driver circuit among the controller circuits.

The reason for using two motor drivers is that one driver is required for each of the front/rear and up/down control in the leg seat, so it is configured like this.

A strange sound occurs during circuit configuration and testing, and we ask a question to determine the cause of the noise.

Symptoms include:

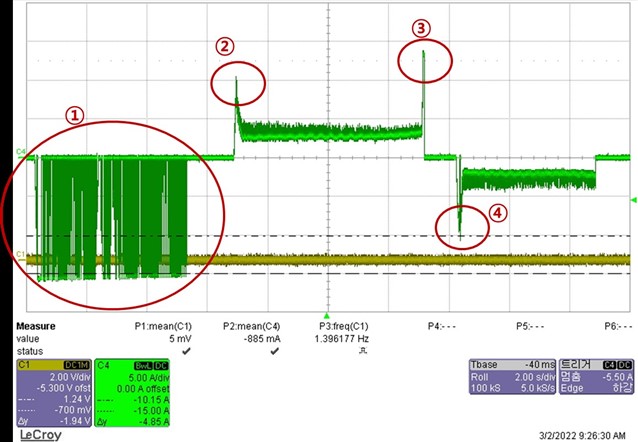

① Section: Current magnitude in the section where the folding switch is continuously pressed while the seat is folded

② Section: Current magnitude in the section where the switch is first pressed to move the seat up

③ Section: Current magnitude when the seat is moved to the uppermost position

④ Section: Current magnitude in the section where the switch is first pressed to move the seat down

If you look at the current waveform in the 4 sections above, you can see that the current is more than 10A, and a “tick tick” sound occurs in this section. (Check the attached video_'noise generation video')

The customer expects the noise (shattering sound) generated by L (inductor) in the CLC circuit configuration of the power part.

The L (inductor) used in the circuit is 7443320100 (Wurth Elektronik), and the same inductor used in TI's EVM board (DRV8244S-Q1LEVM) was used.

Q1) Is this noise caused by the inductor as expected by the customer?

Q2) Or is there another cause?

Q3) Is there a solution depending on the cause of the noise? Could you please let me know if you have a guide?

Please check. Thank you.