Hello expert friends,

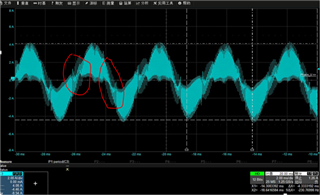

Our SW friend tried to use FOC to drive one motor by DRV3245E-Q1 with 3 shunts, it worked but we don't know whether it is standard FOC result. If there any standard for checking BLDC current waveform by FOC, who can help to provide some suggetions or materials?

Thanks in advanced.

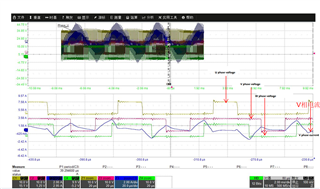

Fig. 1 Motor light load test results