Other Parts Discussed in Thread: MCF8316A

Hello,

I was going to validate the DRV8316REVM using the GUI but I am running into a few issues.

Using the InstaSPIN GUI seems to always overdrive the motor that I am using and it ended up shorting one of the motors today. Motor Identification looks like it works but the moment I try to drive the motor after that, the motor starts to jitter and draw a lot of current.

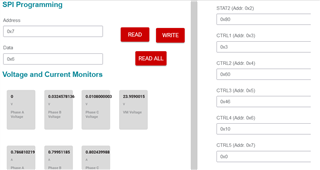

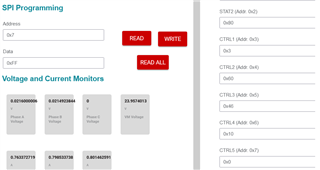

On the other hand, I tried using the Sensored Trapezoidal GUI and it worked flawlessly with the same motor at much lower currents. The only problem is that I can't seem to write to the SPI registers with this GUI.

I can always just write my own code, but if this can be fixed this way would be a lot easer. Let me know if I am doing anything wrong.

Jerome