Other Parts Discussed in Thread: TMS320F280025C, TMS320F280025, C2000WARE-MOTORCONTROL-SDK, DRV8323, LAUNCHXL-F280025C, INSTASPIN-BLDC, BOOSTXL-DRV8323RS, DAC128S085EVM, C2000WARE

Dear Aaron,

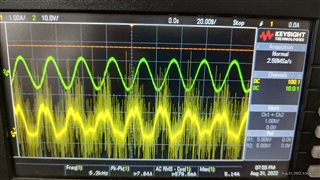

we are interfaced drv8343 with msp430f5529c(non automotive) mcu with Trapezoidal-sensorless BLDC motors control algorithm , successfully tested on rig upto 9000 rpm .

now we are trying to replace the c2000 family of TMS320280023 (automotive qualified) MCU with drv8343 driver ic ,

initially trying to interface tms320f280025c launch pad kit with DRV8343S evb board in going to use power module.

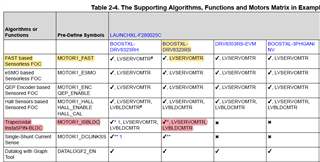

i have taken as a reference universal_motorcontrol_lab_f28002x sample project trying to replace DRV8343S instead of DRV8323S, here both driver IC hardware abstraction layer is completely different .

please let me know , which is the most suitable for tms320f280025 WITH DRV8343S Driver IC sample project for (demo source code for software) and hardware for the new development.

Please send supporting document and give your feed back ...

Thanks .

Bhuvanesh.

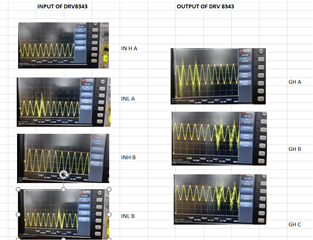

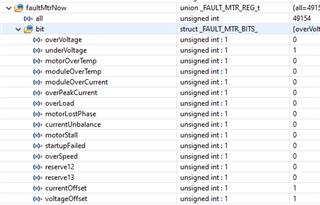

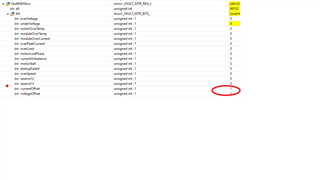

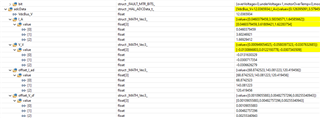

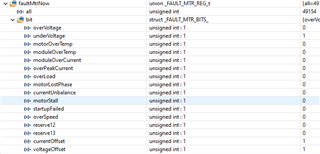

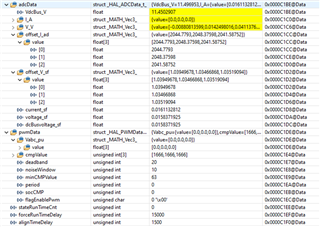

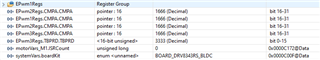

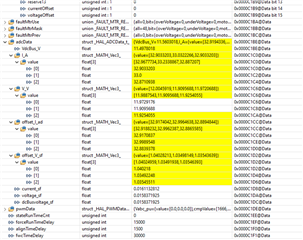

successfully interfaced drv8343 with c2000(f280025c MCU)

successfully interfaced drv8343 with c2000(f280025c MCU)

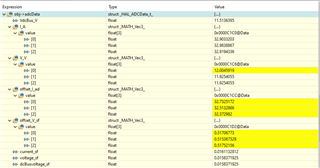

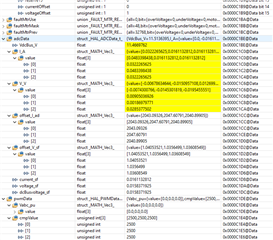

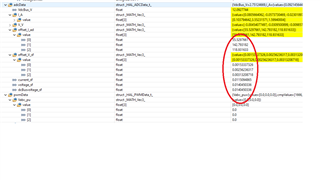

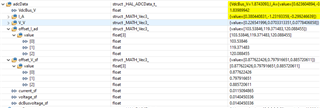

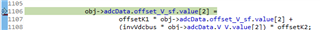

and we,get the blow voltage and current offset value

and we,get the blow voltage and current offset value