Hi support team.

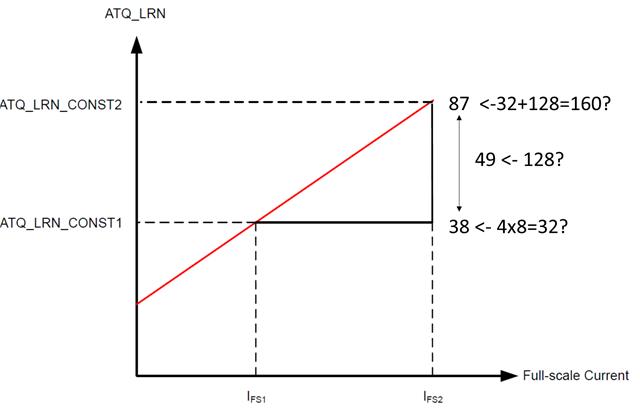

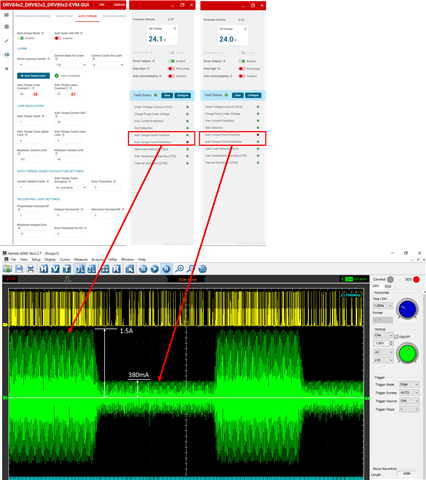

I have a question regarding the auto torque parameter setting example in the datasheet.

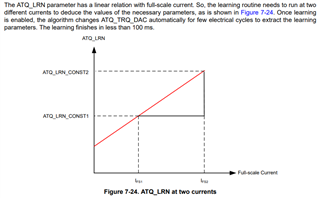

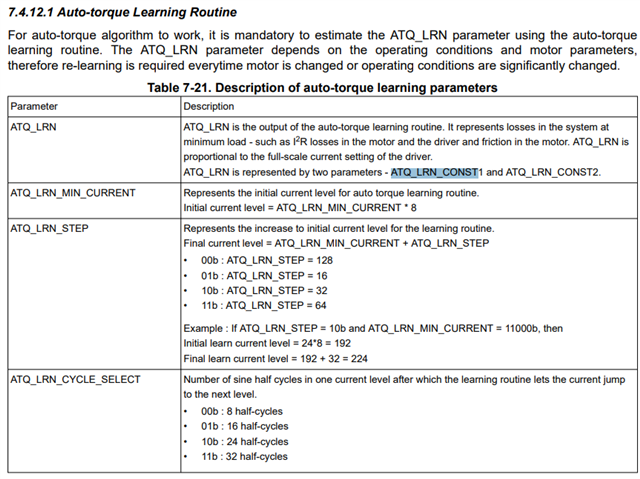

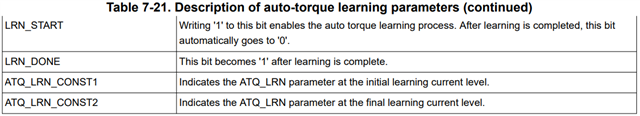

I found the following in the datasheet.

I have set the initial current setting to 740mA, but isn't it possible to set 740mA?

Initial current level = ATQ_LRN_MIN_CURRENT x 8, and ATQ_LRN_MIN_CURRENT has a maximum value of 31, so the maximum initial current level setting is 248.

If my understanding is wrong, could you tell me the setting parameters for the initial current level 740mA?

![]()

Best regards,

Higa