Other Parts Discussed in Thread: DRV8323

I've had an ebike system running flawlessly, with a sensorless, Instaspin, FOC, C2000 device + DRV8301, for the last five years. All of a sudden the system fails with the fault isolated down to the DRV8301. Upon inspection it appeared as if a small fleck of solder, or similar, could have landed across two pins and shorted them together, causing the failure. The DRV8301 was replaced, in situ, and the system sprang back to life. It then failed again a couple of days later.

Obviously the first failure wasn't caused by a fleck of solder.

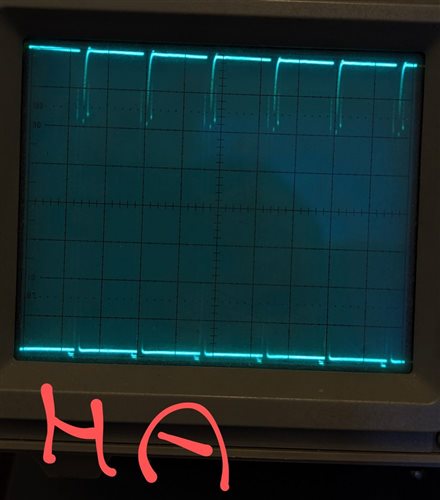

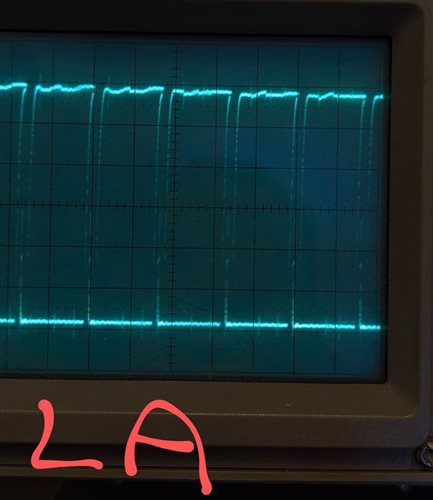

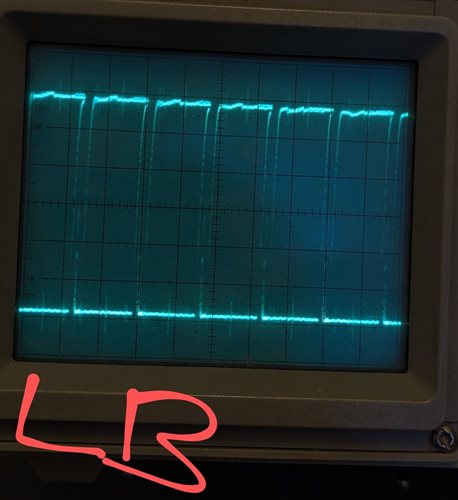

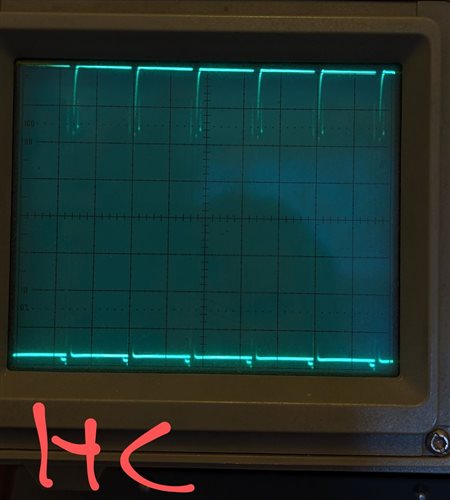

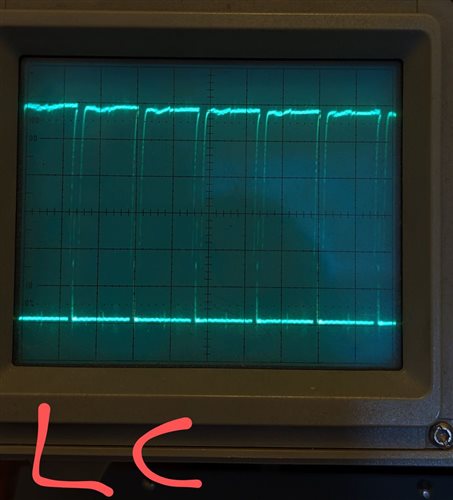

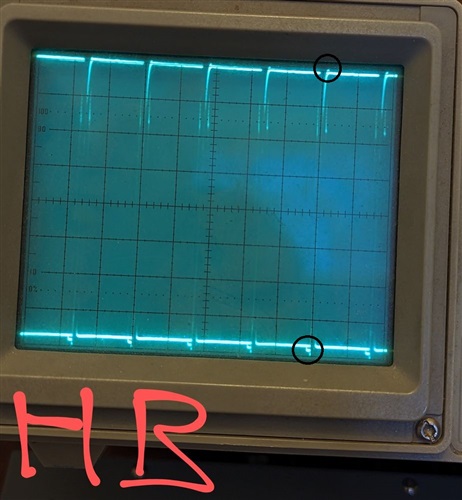

The faults have been isolated to the high side gate drivers and are relatively minor as faults on these forums go. First time SH_C and GH_C ended up shorted internally @ about 4 ohms internal resistance. Second time SH_B and BST_B ended up shorted together at about 20 ohms. Interestingly neither of these conditions were enough to affect the charge pump to the degree that the system stops working and a fault flags. The associated high side stops but the system still gives it's best shot at spinning the motor. It works but at significantly lower power output and the harmonic content shoots up (away from sinusoidal drive) so the acoustic noise increases.

Having gone five years with reliable operation I do not think that layout, component choices, or system tuning is to blame. More component values/performance drift/component failure over time could be the most likely culprit. Sadly I do not have the PCB layout anymore but given how reliable it's been, up until now, I do not think that's to blame. The gate drivers are configured for their lowest peak current delivery and 10 ohm gate resistors are used. The MOSFETs have a total gate charge of 89nC and the system is set to run at 30kHz (well within the DRV8301s capabilities). A TVS is installed across the supply along with 1000uF of bulk, low ESR, capacitance. The supply is a high current lithium ion battery pack so sinking back EMF shouldn't be a problem. The TVS hasn't been positioned specifically to protect the DRV8301 and the battery is a considerable distance away, as parasitics go, so that's not completely ruled out.

System nominal is 48V and the system drives up to a limit of 18A as set in the Instaspin software.

I obviously realise that this is a bit of a needle in a haystack, but given the way in which the high side gate drivers have failed, is this failure, after years of use, indicative of anything in particular I can focus on in terms of solving this problem?

Clearly something has changed within the system but I would rather isolate, and diagnose the issue, instead of replacing all the power components and hoping that fixes it. Scoping the gate drive signals would be the first thing I'd want to do but I figured I would ask here first before I go poking around as that always comes with the potential for causing further damage.

Many thanks,

Matt.