Other Parts Discussed in Thread: DRV8323, MSP430FR2355, DRV832X, MSP430F5529, CSD19506KTT, BOOSTXL-DRV8323RS, TIDA-010056

Hi team,

My customer need assistance.

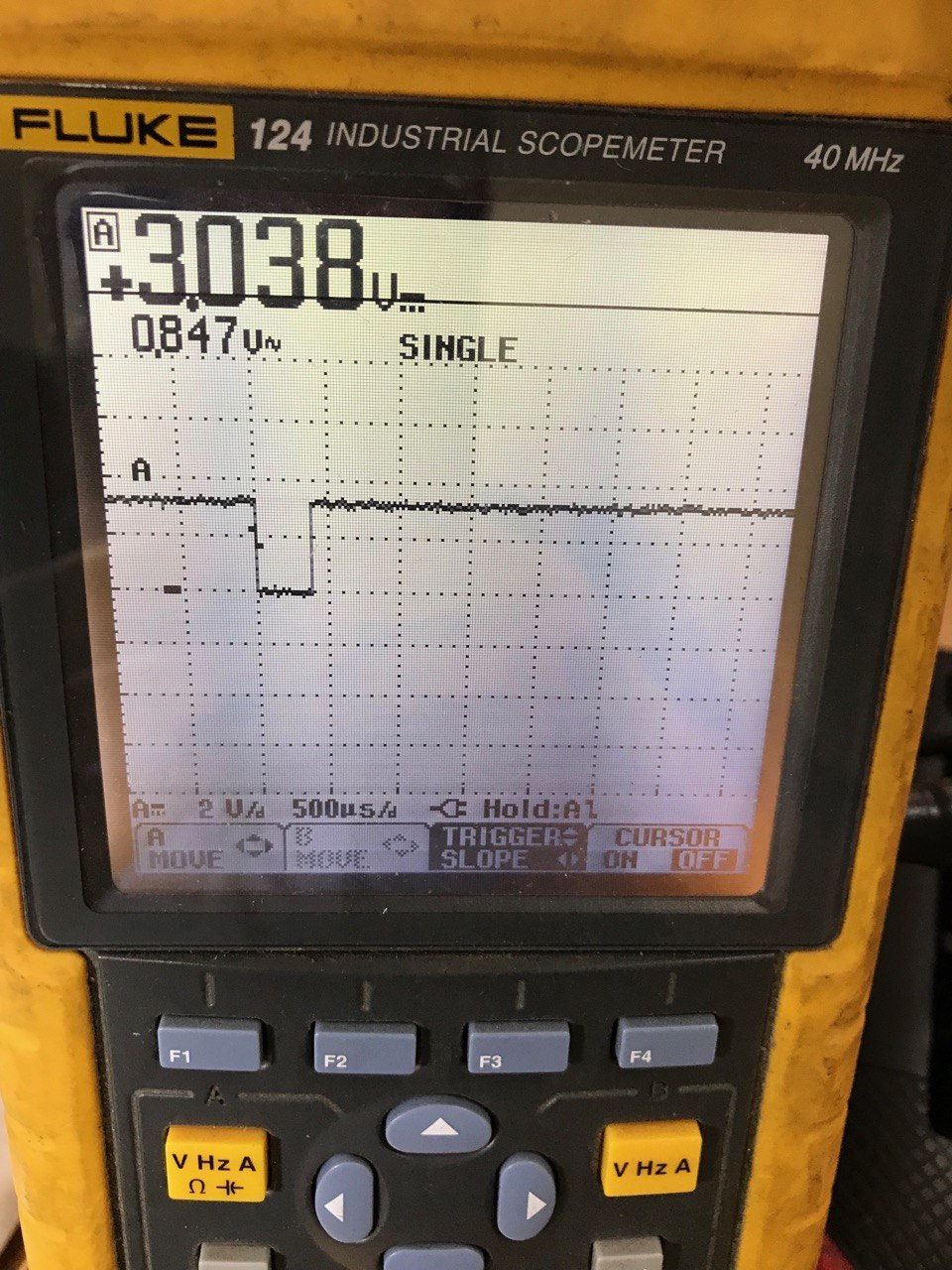

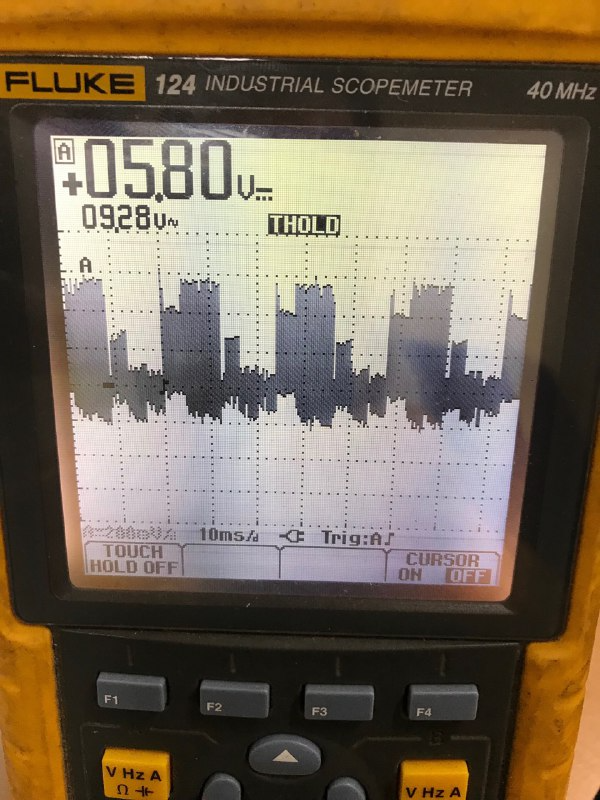

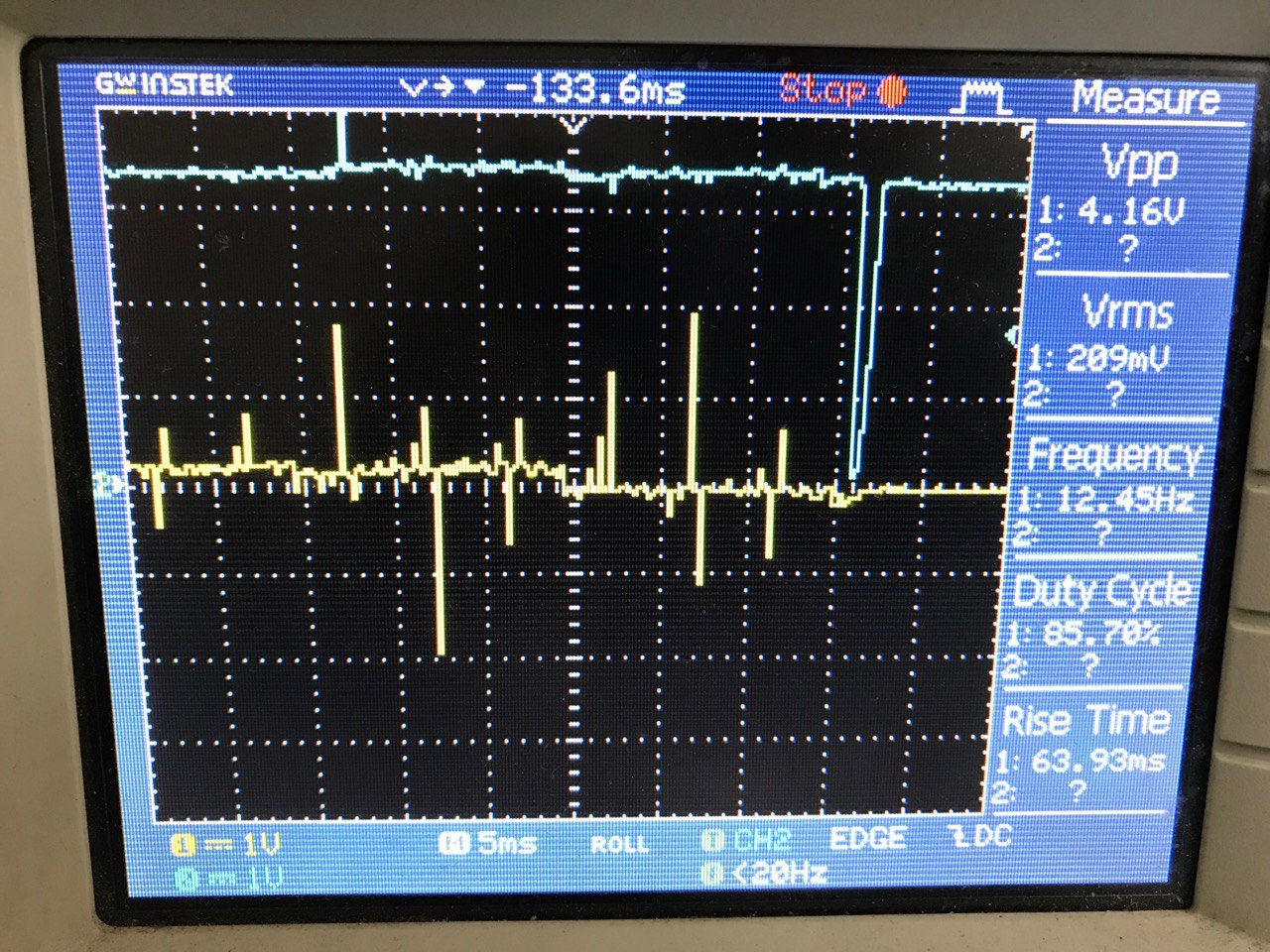

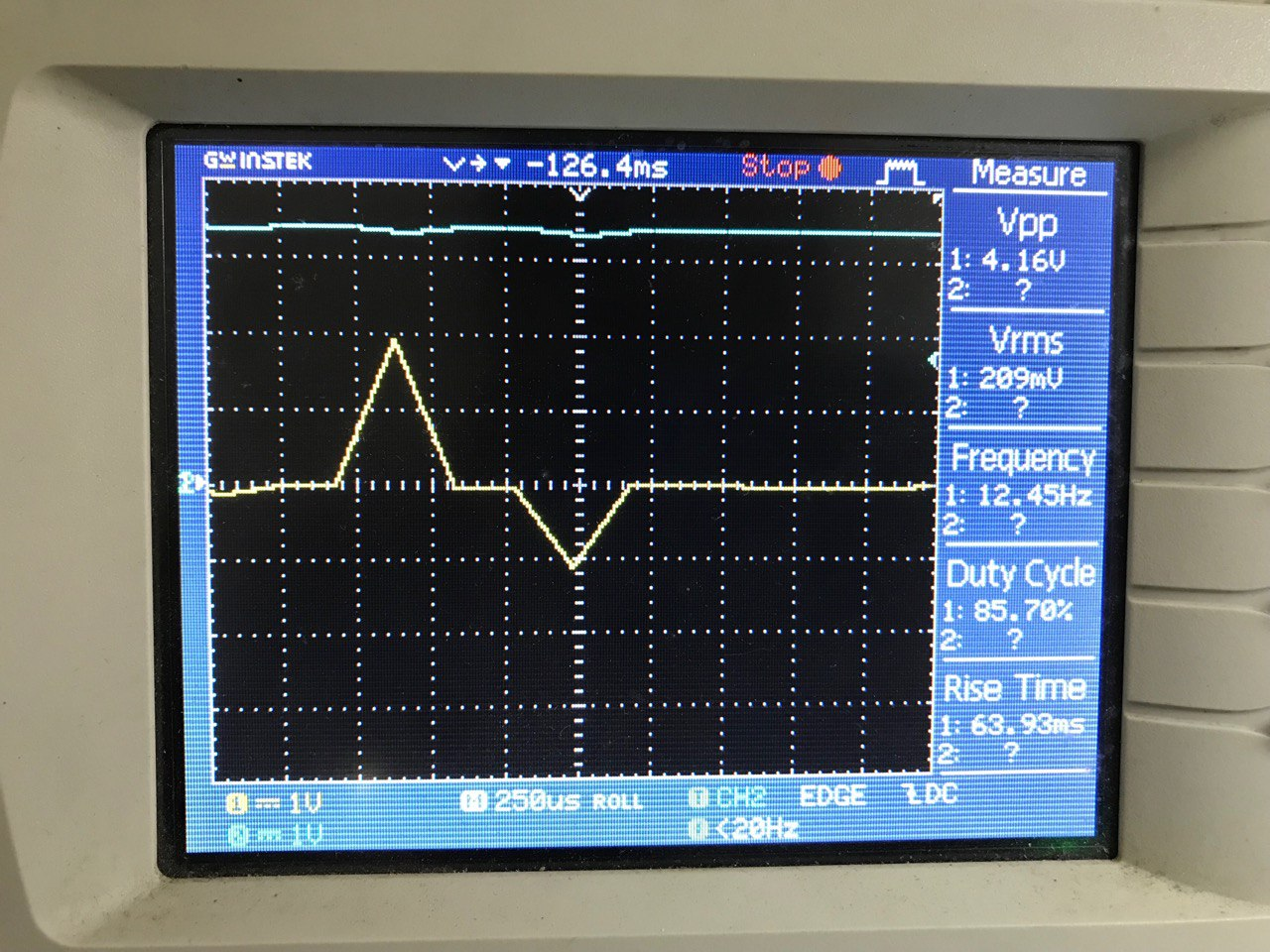

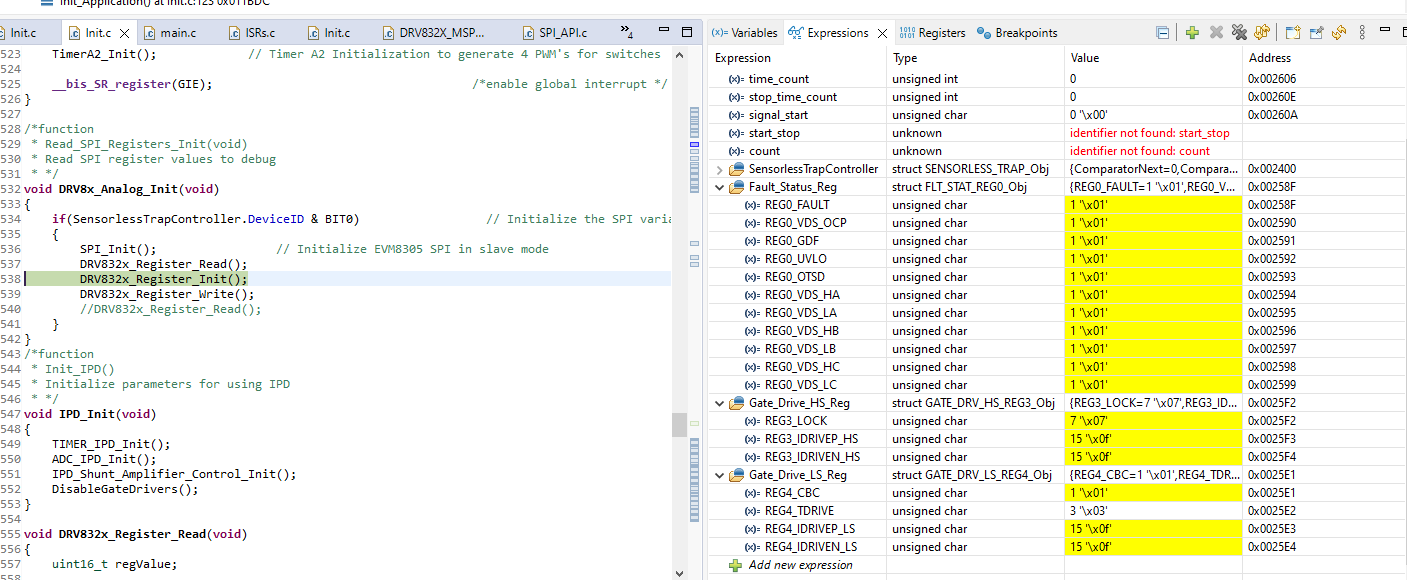

I have designed a PCB similar to BOOSXL_DRV8323RH, using DRV-8323RH to control a BLDC motor. I have used MSP430FR2355 to control it. During the debugging process, the fault pin of DRV8323 produced an active low pulse that triggered an interrupt on the MSP430 and initiated an interrupt service routine (ISR) to report the fault.

I have checked, but I am unable to identify the location of the error. Please help me resolve it

MDNN schematic.pdf