Other Parts Discussed in Thread: MCF8316D, MOTORSTUDIO, MCF8316C-Q1

Hello TI Team,

I’m working with the MCF8316A and observing an issue where all three phase outputs (OUTA, OUTB, and OUTC) show identical waveforms (square waves with no 120° phase shift). The motor does not rotate.

Hardware setup:

-

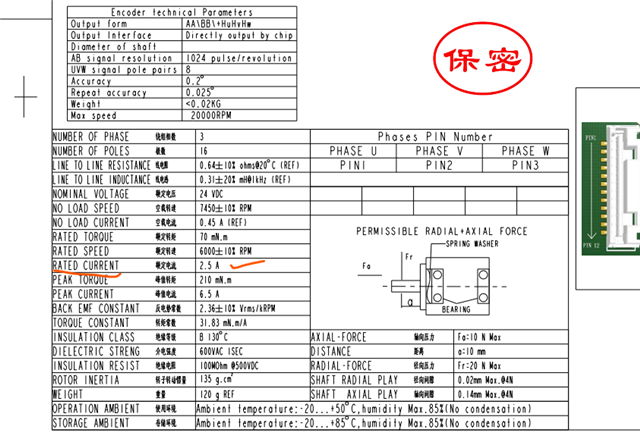

Motor: BLDC, 2-pole, rated for 24 V

-

Supply: 24 V DC

-

Driver: MCF8316A

-

Controller: STM32H755ZI Nucleo board (I²C used for configuration and register reads)

-

PWM_SPEED pin connected to PB0 of STM32 (providing ~15 kHz PWM duty for speed input)

-

DIR and BRAKE pins controlled by MCU GPIOs

-

OUTA/B/C probed at MCF8316A output pins (not MCU pins)

Symptoms:

-

When I probe OUTA/B/C, I get three identical square signals (no phase shift).

-

The ALGORITHM_STATE register reads MOTOR_MPET_KE_MEASURE(0x0014).

Despite that, the motor doesn’t rotate and output waveforms remain identical.

What I have tried:

- Confirmed supply voltage stable at 24 V, SPEED_MODE in PIN_CONFIG register is set to 01b.

- Checked the GATE_DRIVER_FAULT_STATUS, there are no faults.

- Checked the CONTROLLER_FAULT_STATUS, there are no faults.

- Tried changing ALIGN_ANGLE to 120°, but no change in output waveform.

Questions:

-

Why are all three phase outputs (OUTA/B/C) producing identical waveforms?

-

Does ALIGN_ANGLE influence output waveform phases, or is phase shift only active once the motor starts rotating?

-

Do I need to explicitly trigger a commutation start command after alignment?

Any insights or debug steps to confirm if the MCF8316A is actively commutating would be greatly appreciated.

Thanks & Regards,

Aniruddha P