Hi at all!

I am trying to control a steppermotor with a resolution of 400 full steps per revolution (0.9°) in indexer mode with 256 microsteps.

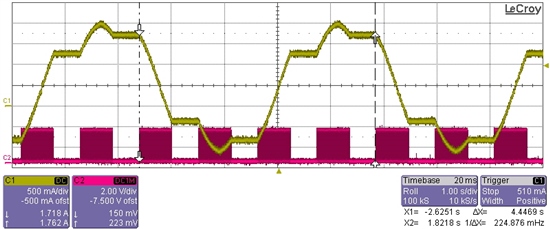

The problem is, that the motors movement isn't smooth. The motor is cogging each time a full step is reached.

Currently I am using following parameters:

- Dead Time 400ns (CTRL Register)

- Off Time 500ns (OFF Register)

- Blanking Time 2us (BLANK Register)

- Fast Decay mode at all times (DECAY Register)

I am using the DRV8711EVM developement board and a stepper motor with 1.33A/phase, 4.2mH/phase, 2.1Ohms/phase and a voltage of 24V over the h-bridges.

Can somebody tell me which parameters I have to change to get a smooth movement of the motor.

Kind regards,

Michael