Other Parts Discussed in Thread: DRV8353, DRV8323

Hi,

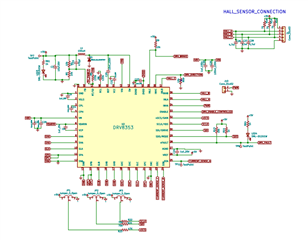

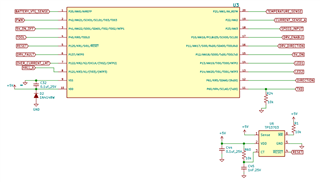

I'm using DRV8353RHRGZR for our motor control application and stuck at final proto testing.

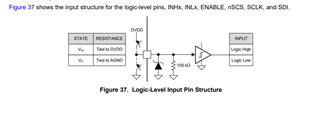

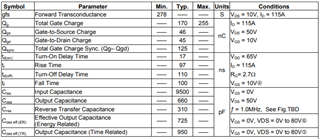

using it in 1 x PWM Mode, many time's their is 800mV on(INHA pin)PWM input pin which is connected to MCU and (INHC pin) Direction pin which is pull down by 10K resistor,

Due to the voltage on the PWM pin((INHC) the gate driver consider it as 100% duty cycle and then all goes wrong, I've replace the IC but still their is voltage on both the pin's.

My observation: whenever I change the direction of the motor by using the Direction pin ((INHC) from that instant their is voltage on the that PIN