Other Parts Discussed in Thread: DRV8434, DRV8424

Greetings,

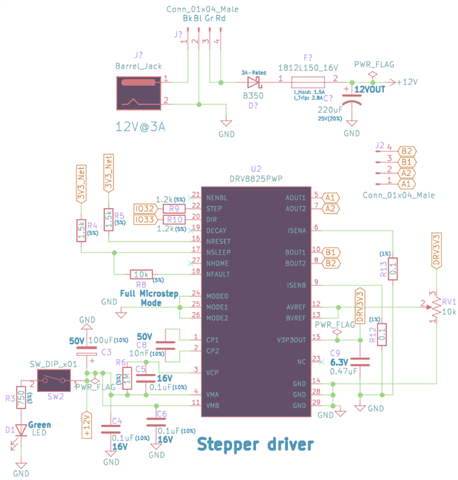

I'm intending to drive a 28HB30-402A stepper motor (Current phase: 1.0A --- Resistance phase: 2.4ohm --- Inductance phase: 1.8mH) with a drv8825 driver supplied by a 12V @3A (schematics attached); according to the current regulation guideline (Datasheet p19), with a sense resistor value of (0.1ohm) and my motor peak current, Vref (5 x Rsense x IFS) should be adjusted on somewhere around ~0.5V and considering the (71/100)% current limit in full-step mode this could roughly get to ~0.7V (please correct me if I'm wrong). My problem is using the trimmer and adjusting the Vref on anywhere below 1.2V results in stepper motor to vibrate (no rotations) and squeaking, and above 1.2V stepper rotates but squeaking remains...still, 1.2V for Vref is way higher than the calculations and I'm wondering if I've missed something in my circuit design. Your feedback is greatly appreciated.

Regards,

Amin