Other Parts Discussed in Thread: DRV10983

At the recommendation of Krushal and Innocent, I have replaced the 10983 with the 10987 part on my 109893 TI eval board. I have been struggling with optimizing the 10983 with my small blower and Krushal recommended the 10987 for reasons of more reliable current limit tripping.

I installed the new 10987 gui (Version 3.2.2) by using the installer supplied by TI.

Power up and gui connection worked fine, but right off the bat I have issues simply trying to drive the motor in open loop. No matter what my settings are in the startup settings, the part is not behaving as expected. I have tried many different combinations of setting simply trying to get the driver to cooperate and run in open loop.

My motor drives a small plastic impeller 3 inches in diameter and 0.25 inches thick: this is a small low inertia object.

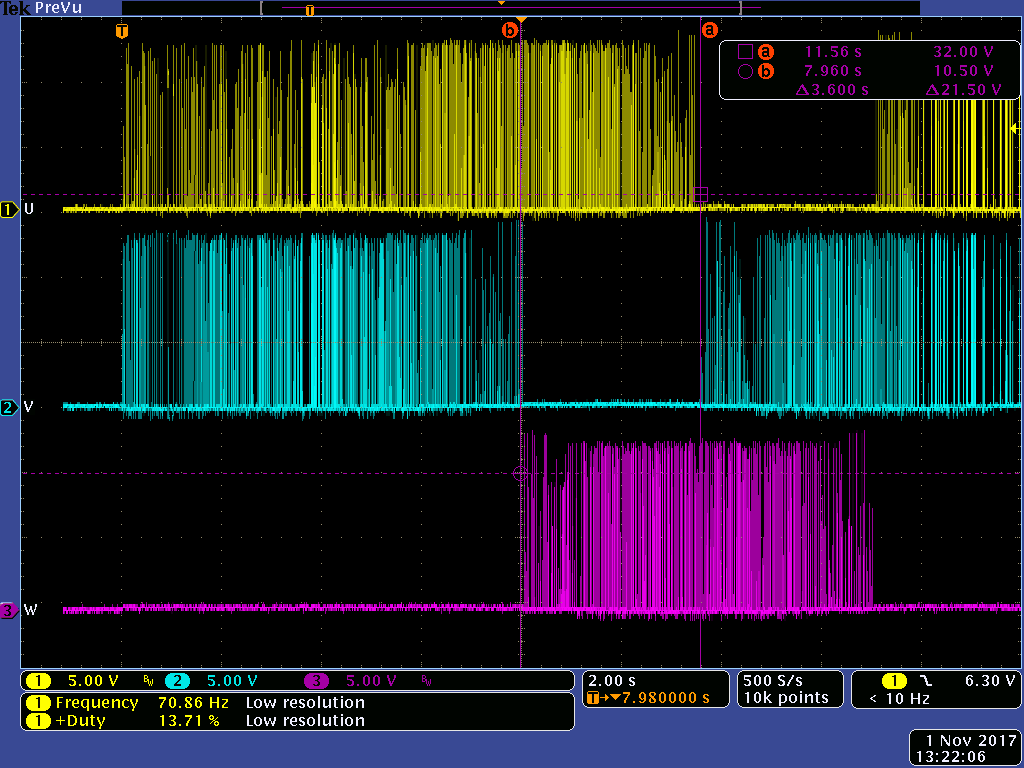

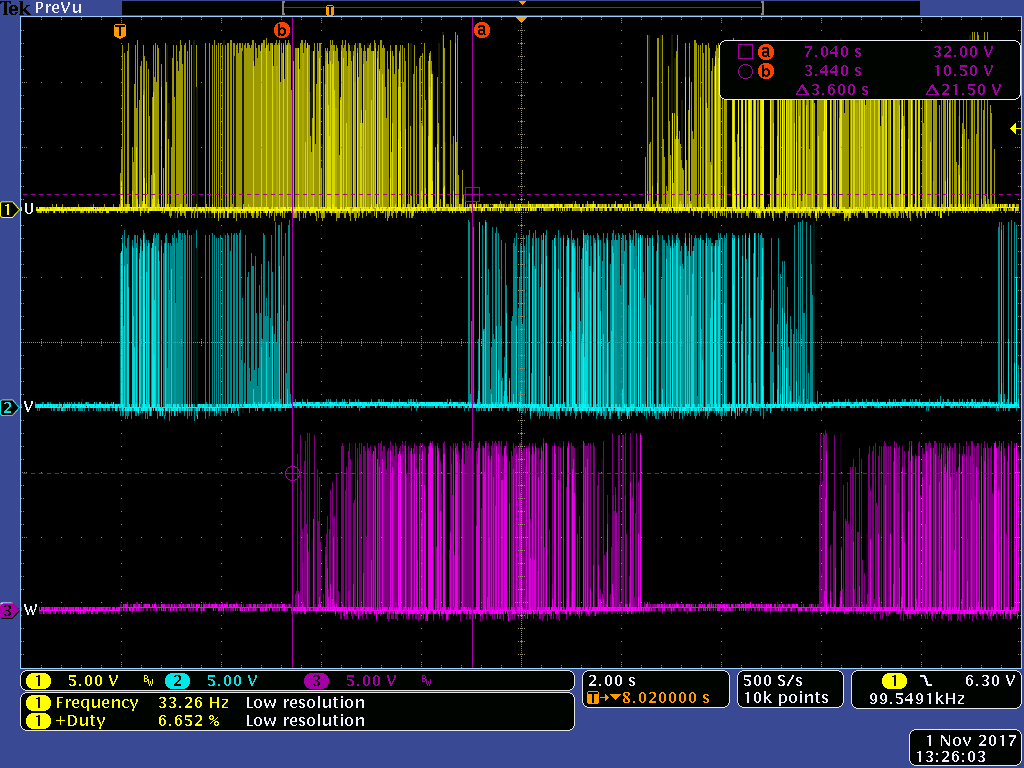

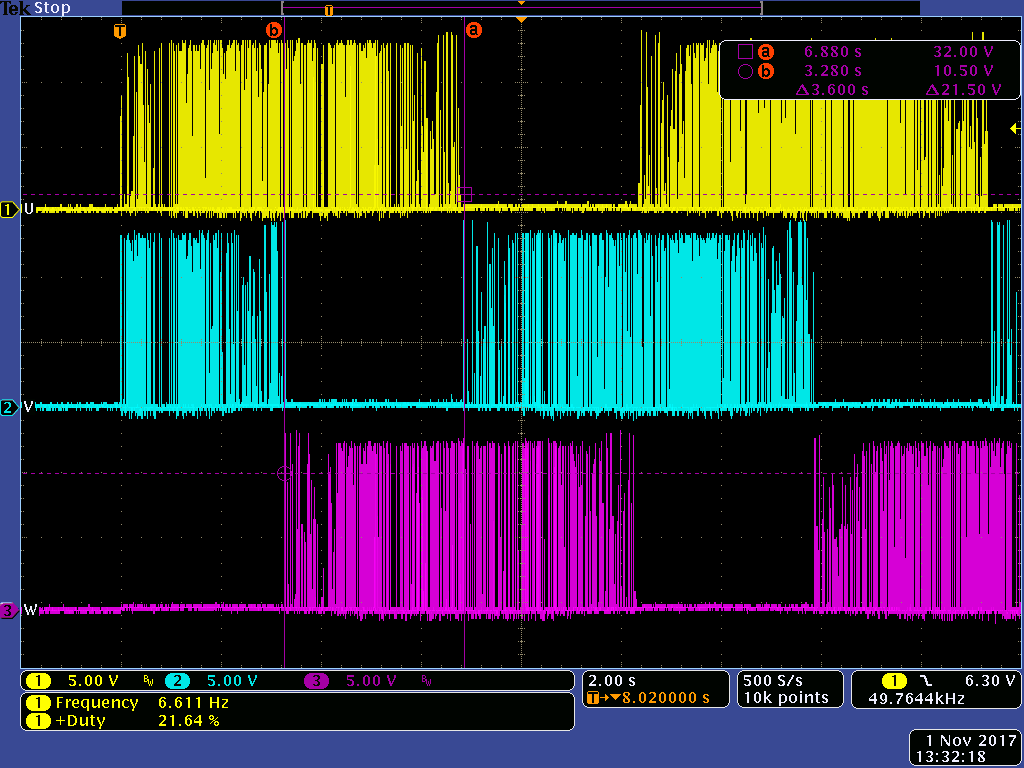

The symptom is that the 10987 never issues a DC level to align - after a couple seconds to download the registers (after setting speed to non zero) the U and V phases are PWMed for 8 seconds and then the part enters a 'stepping sequence' at about 3.6 seconds per step. Screenshots below.

Other than the setting below I am ignoring ALL settings in the gui. A snip of this is shown below.

Software current limit = Disable

Phase Resist = 698.4mohm

Kt = 18.5mv/Hz

Acceleration Range Selection: Fast

FIrst Order Accelerate: 0.9Hz/s

Second order Accelerate: 0Hz/s

Align time: 5.3s

Open to Closed loop Threshold: Not applicable

Open loop current rate: 6VCC/s

Open loop align current: 1.6A/1.2A

Bottom line questions:

1.) Why is align immediately current limiting (the very first pulses on U and V is 500ns wide.) If I adjust the open loop/align current smaller, even more agressive current limiting occurs. The current indicated on my power supply during this align period is 150ma.

2.) Why is the spacing between the first open loop 'step' so long (3.6 seconds?)

3.) I do not witness correlation between the register settings and operation of the part.

4.) After going through the standard installation using the TI tools (which included a python installation) I get an error when trying to lauch the python tool. (I also downloaded and installed python 2.7 directly from the web with the same results.) I only need this to debug what's happening with the register settings.

5.) Is it true that with the CLoopDis bit checked in the gui that the align step is bypassed after the first attempt? If I stop the motor by writing 0 to the speed register and then (attempt to) start by writing a non zero number into the speed register, the does go through the (incorrect) align sequence. This makes diagnosing the 'missing DC align sequence more difficult.

Thanks for the help,

Doug

Screenshot of final settings (result after scope sequence below.)

Screenshot of initial align with align time set to 5.3s and first order accelerate set to 0.9Hz/s. Note 8 seconds of PWMed align followed by an initial 'step' of 3.6s in width.

Screenshot of initial align with align time set to 0.67s. Note about 3.5 seconds of PWMed align followed by an initial 'step' of 3.6s in width:

Screenshot of initial align with align time set to 0.67s and First Accel set to 9.2Hz/s:

Missing Python complaint from gui: