Other Parts Discussed in Thread: DRV8830, DRV8832

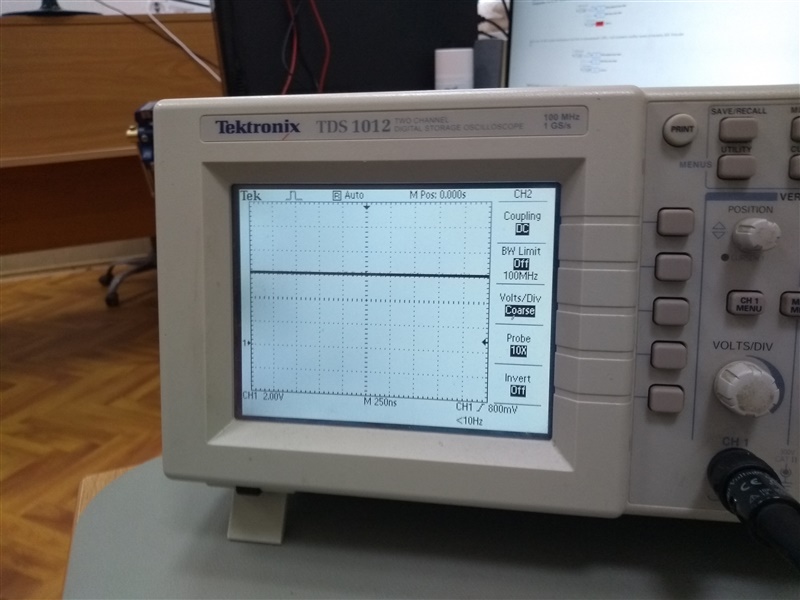

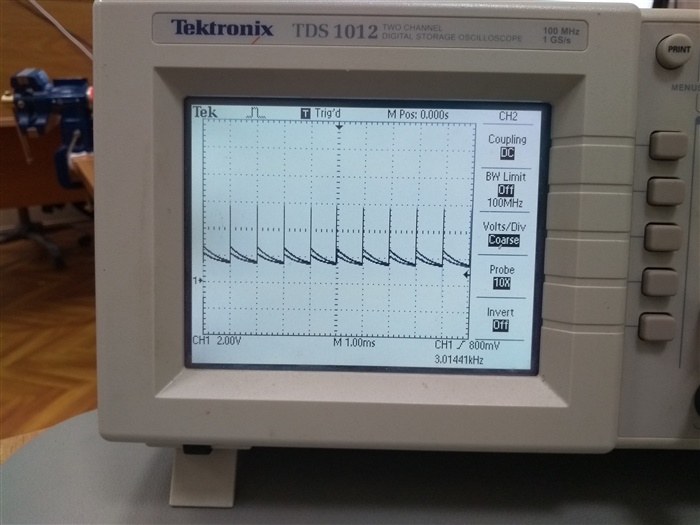

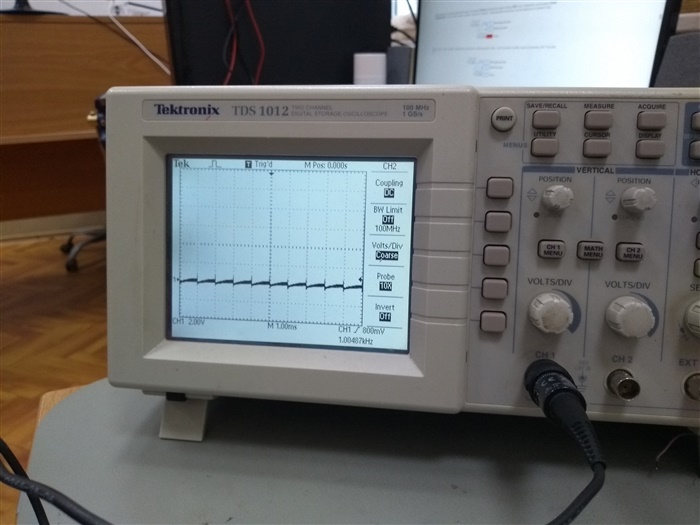

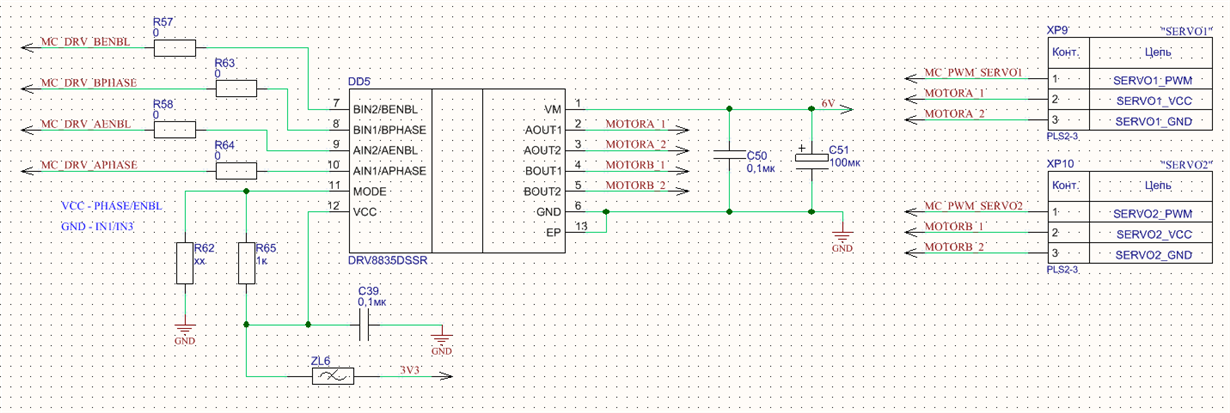

Hello! In my project I decided to use DRV8835DSSR. And i got a problem: the micro servos KST X08H V5 and MS325 does not work when power is connected through the driver. The driver is used in this case in key mode, simply as a voltage switch (on/off). This is done so that there is the potential to use a DC motor instead of a servo and control the rotation speed via PWM through the driver. MODE = VCC, AENBL = HIGH level, APHASE = HIGH level from the STM32 F205RET microcontroller. At the output AOUT1 there is a low level (I connect it to the black wire of servo), at AOUT2 there is a high level 6V (I connect it to the red wire of servo), but this voltage is when servo is not connected. The control signal (yellow wire) comes directly from the microcontroller. On the oscilloscope i watched a control signal and everything is fine, the frequency is 50 Hz, the pulse duration is 1500 microseconds. If powered directly from the voltage 6V, the servo works, angle changes. However, if through the driver, there are dips on the VCC and GND signals, DRV8835DSSR restarts every 1 ms. I tried to connect driver to the DC motor from the disassembled servo X08H and it works, as well as other motor Maxon 2W also works. But servo doesnt work through this driver. Maybe you can help, how to fix this problem? Any idea? I want to use servo, but also want a potential opportunity to use DC motor. I use a standart connect circuit, as specified in the datasheet. I send you the circuit part and waveforms. Thank you!