Hi,

Iam finding the DC Brushed motor drivers. here is my requirements,

1.> I need to control 24 DC brushed DC motors, is there any technique or any Driver which can handle 24 motors.

2.>I need to sense the current flow through the DC Motor.

3.>i need also position feedback of the motor.

I found DRV8833 driver, its dual one, so i need to use 12 DRV8833 chips in my design but 12 qty is more, i need to reduce the count, bom cost and size of the PCB

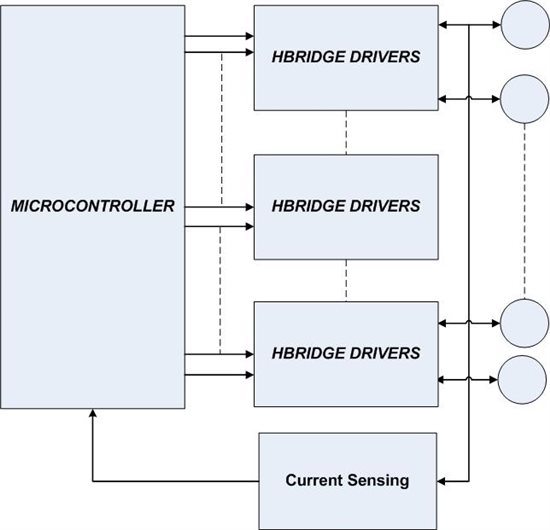

if i use DRV8833 i need to use ADC for current sensing of all 24 motors but this technique seems again which will increase number of components in the board. i need to reduce the number of components in the design, please find attached block diagram.

I need to reduce number of PWM pins of the micro-controller , number of Hbridge drivers and current sense ing circuit as well. can you please suggest what is best way i can reduce current sensing, number of Hbridges and number of pins of micro-controller(I need to control 24 DC brushed Motor).

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.