Hi experts,

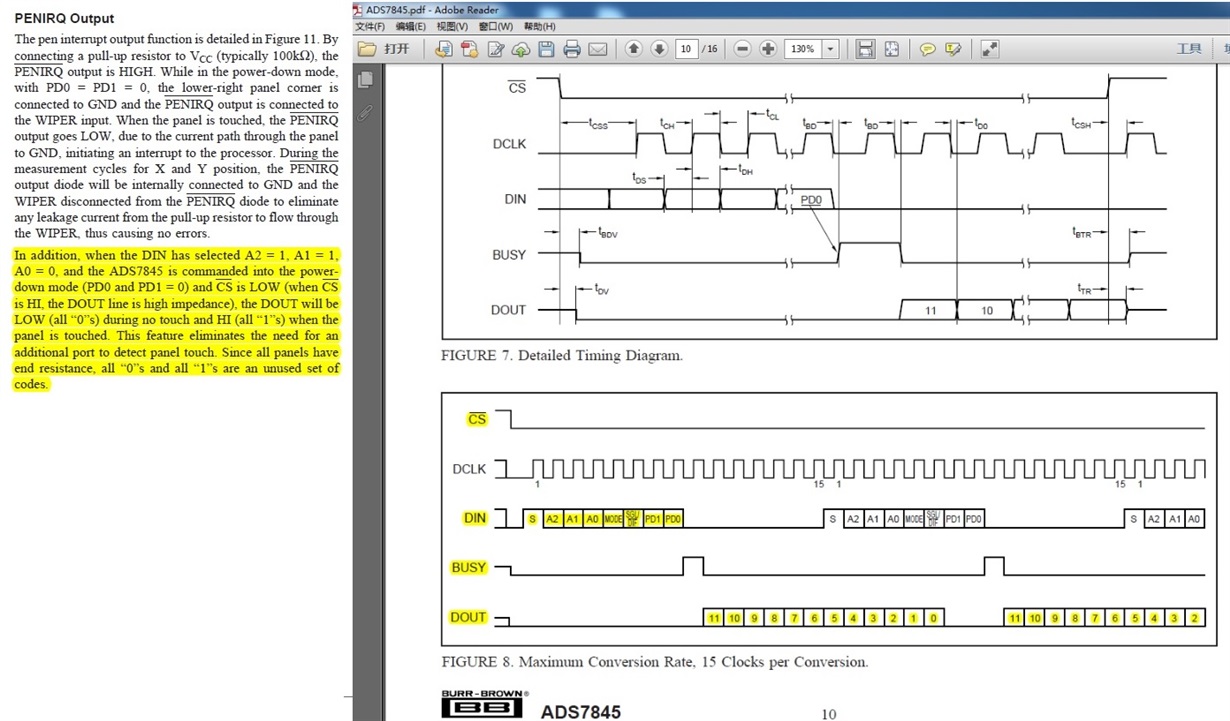

We are testing our ADS7845, but we found the datasheet mentioned: the DOUT will be 12bit all High when the panel be touched. datasheet Page 12.

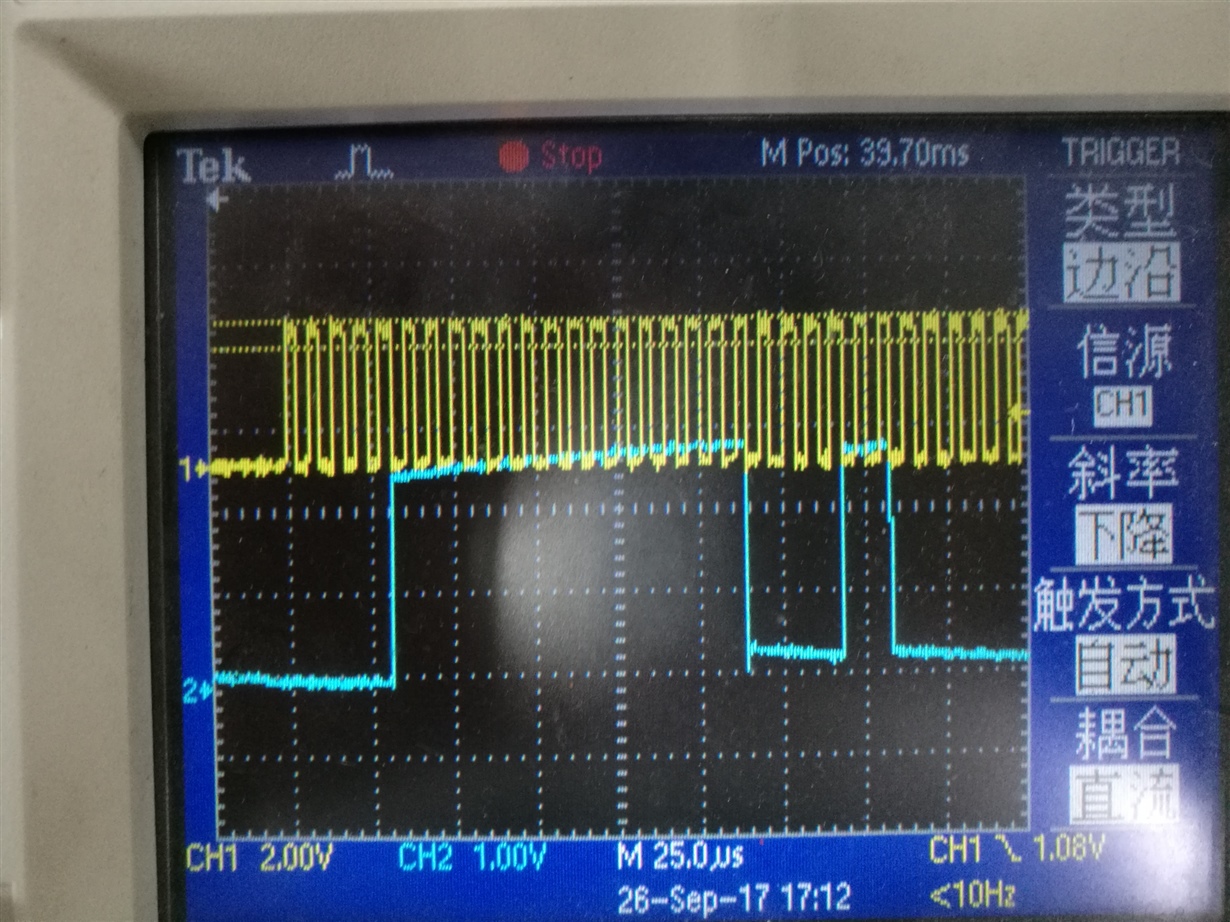

But during the test in customer's board, we found the MSB 11bit is all high, but the last LSB bit[0]=low.

So could you please help double confirm whether customer's board is something wrong or ? thanks.

Best Regards

Iven Xu