Part TPLD740LD will be destroyed in a series ( White goods project) and I can´t find the root cause

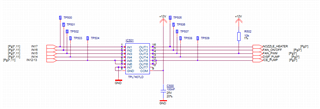

Schematic

Connected are only 2 Outputs (Nozzle Heater 1,9W + FAN 1,2W)

Controller Voltage is 3V3. The 3V3 are generated via a DC/DC buck

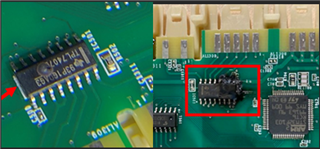

The destroyed parts look like this

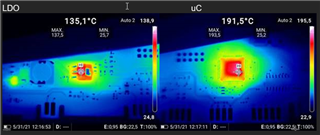

The LDO and the uC are getting very warm

My first thought was a shortcut of one Output, but with this I was not able to reproduce the failure,

The next thought is a possible damage of the internal LDO, but what could be the reason for this or how can a reproduce the failure?

Thanks in advance for your support