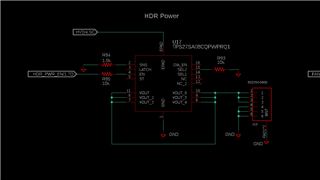

I'm using the TPS27SA08-Q1 part in a new design. Because I do not need the diagnostic information I followed Table 6.2 of the datasheet. SNS is tied to GND with a 1.0kOhm resistor. LATCH, /ST, SEL1, and DIA_EN are floating. SEL2 is tied to GND with a 10kOhm resistor. EN is tied to my microcontroller with a 10kOhm resistor and the microcontroller has a 3.3V logic high.

When the input voltage, Vbb, is at 24V everything works correctly. When EN goes high to 3.3V the part is enabled and I get 24V at Vout.

When Vbb is at 12V the part does not work. When EN goes high Vout stays at 0V. I've tested this with no load (open circuit) and with a 150 Ohm resistor as the load.

There is no protective ground network diode in my circuit so the part ground and the microcontroller ground are at the same potential. According to the datasheet Table 7.5 EN PIN CHARACTERISTICS, the enable pin high voltage only needs to achieve 2V to enable the part which I am doing. This is valid for Vbb over the range of 3 to 28V. Why doesn't this high side switch turn on when the enable pin is at 3.3V and the input voltage is at 12V?