Other Parts Discussed in Thread: TPS27SA08

Hello,

I have a question concerning retry timing (t_RETRY).

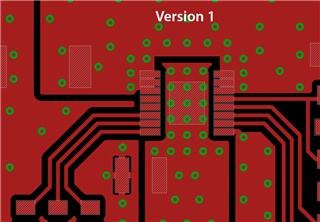

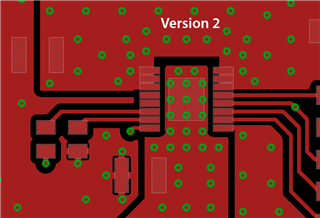

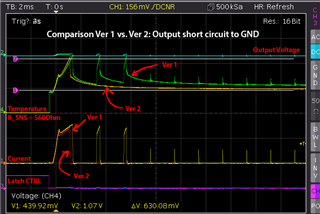

I build a PCB using TPS27SA08-Q1. Testing has been succesful and the retry timing was as expected and as stated in the datasheet (page 9): arround 2ms. That was perfect for my usecase.

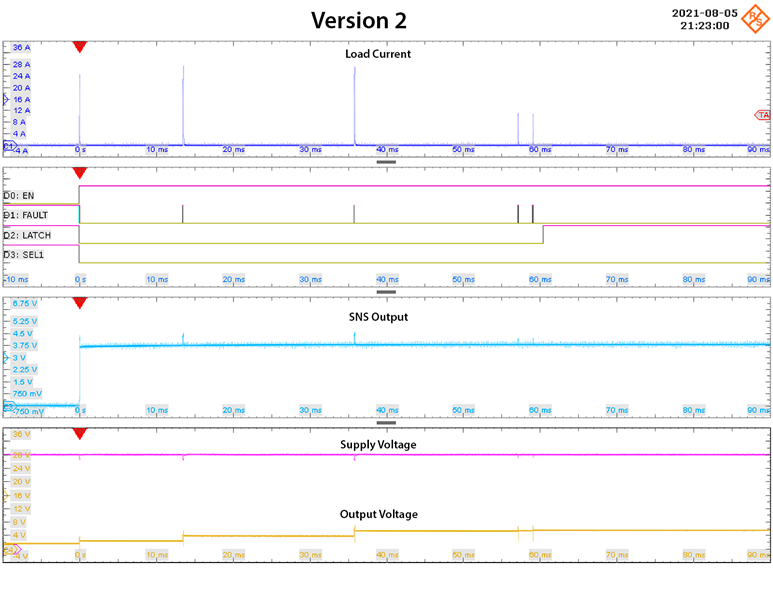

Now I made a new revision of the board and trace layout arround TPS27SA08-Q1 is nearly identical. So thermal coupling should not be an issue. But with this new revison retry timing is completely different. Arround 30ms sometimes even longer. Unfortunately this is not an acceptable time :-(. What could cause this changed behavier? I even replaced the TPS27SA08 to make shure it is not a faulty part. For nearly two days I am resarching for the cause but no luck ...

Any help or ideas would be greatly appreciated.

Thanks a lot an regards,

Bernd