Other Parts Discussed in Thread: TPS65218

Hi Team,

Principally we need to update some of the with “E2” marked default values during the development, so at the prototypes and finally for the finished product, since none of the existing programmed derivates is fitting 100%.

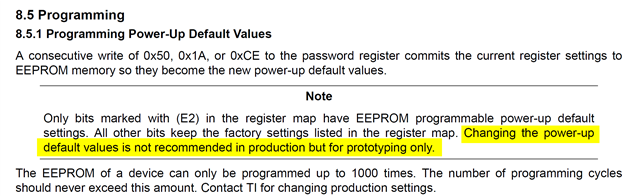

We would like to understand how the yellow marked sentence have to be understood, 1 or 2:

- The final values can be programmed during the production process / assembly and there is the recommendation not change it later in the field, e.g. during an field SW update. (In our case, we do not plan / want to update these settings in the field)

- There is the recommendation not to update at all the default values in the EEPROM for the final product.

If the 2. phrase case would apply, then the internal EEPROM is only intended to be there for development / prototyping purposes?

If so, what would be the process we would need to follow then? Is there a special programmed chip required finally? How would that work?

Best regards,

Simon