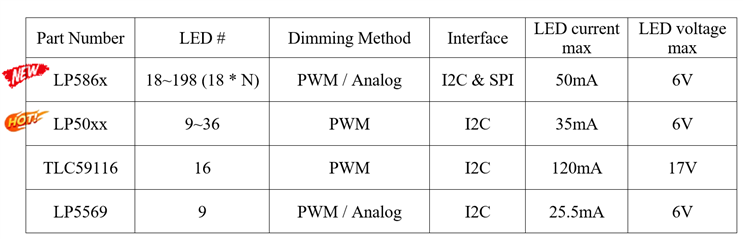

Q1: Why are LP586x better solutions to drive Animated-Amounts-Autonomous (AAA) LEDs?

Q2: How to quickly set up the test environment for LP586x?

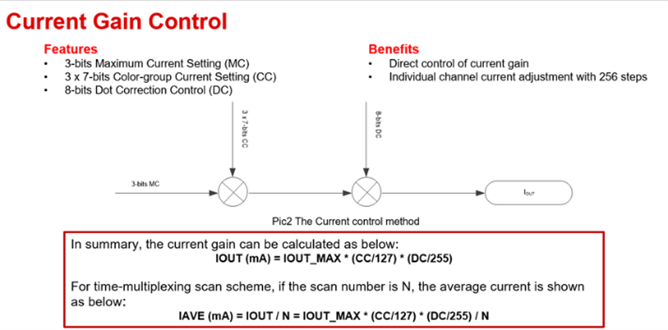

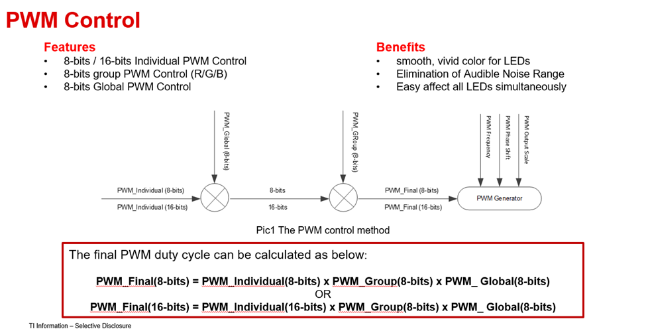

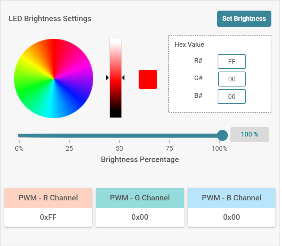

Q3: How to configurate PWM duty cycle and LED output current in the register panel to achieve PWM/Analog dimming respectively?

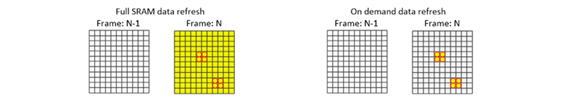

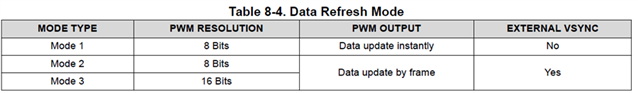

Q4: What are the differences between three data refresh modes in Device Configuration panel?

Q5: How to implement the separate control of LED brightness and color temperature within flexible dimming options?

Q6: Could you provide some relevant resources for LP586x?