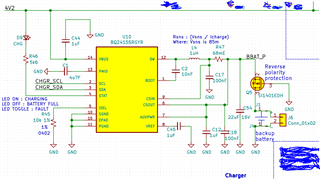

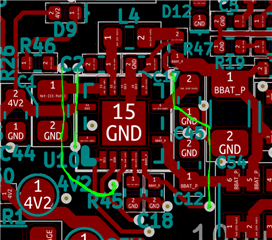

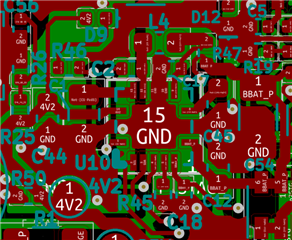

BQ24155RGYR is used to charge a 500mAh Li-po battery. Since this is our latest design we would like to hear from you before sending it to fabrication. Those green colored lines are bottom layer traces connected through vias. Please review this layout and schematic any changes required to better performance please suggest.

Looking forward to your valuable feedbacks.

Thanks,

Ravi