Other Parts Discussed in Thread: TPS562202

Hi,

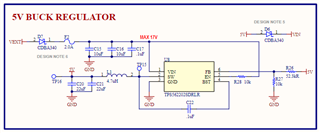

I designed a 5V buck regulator using the TPS562202S IC, which I use to step down a 10 V input. I followed all the design guidelines for this first design, using the recommended component values from table 9-2 of the datasheet, the inductor being this Wuerth Elektronik 74437368047. The circuit seemed to work OK, with a 5V output and about 200 mV ripple at no load and 3.33 kHz switching frequency. Good enough for my uses. Here is the schematic:

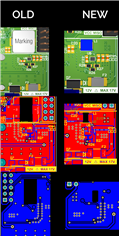

I then swapped the inductor L1, because the original Wuerth was simply too large for my design. I selected this Abracon AMDLA4020S-4R7MT, since it was much smaller and had a high enough saturation current of 4.5 A and a current rating of 3 A. The only difference (that I could see) was that the DC resistance was 70 mOhm (max), vs the 15.5 mOhm (max) of the Wuerth 74437368047. I didn't think that would be a problem. However, this circuit no longer works. Here is an image comparing the two, this is a 2-layer PCB.

Here is an image comparing the output. The old design uses the Wuerth indcutor, the new one uses the Abracon. The old design works, the new one just does not: it is not constant. Sometimes it reaches 2 V (instead of 5 V), then the output matches the input voltage, then it switches around randomly. So, something is definitely wrong.

Questions:

1. Taking into account that both schematics are identical, with only the change of the inductor selection, can anyone notice any errors between the old layout (which works) and the new layout (which doesn't)?

2. The one thing I am noticing now, is that the Abracon inductor reads as "designed for switching frequencies between 100 kHz and 5 MHz" in the datasheet. The regulator does not seem to reach 100 kHz until a small load is applied (say, about 50 mA), and it stays at frequencies below 10 kHz at no load. Could the inductor be the problem? Any ideas?

Thank you in advance for your support.