Other Parts Discussed in Thread: BQSTUDIO, , GPCCHEM

Hi,

I used BQ27621YZFR-G1A gauge to read the battery charge status on my embeded device.

I read the Technical Reference

www.ti.com/.../sluuad4c.pdf

I read the Quickstart Guide

www.ti.com/.../sluuap5a.pdf

BQ27621-G1A was characterized by BQstudio software and the EV2300 interface

I can use 2 types of batteries but only one is available due to component shortage

First battery (unavailable)

Akku Tronics

Model : 103450-PNPLC

Type : Li-polymer battery

Specification : 3.7[V] / 1800 [mAh]

Li-po battery made with pure cobalt

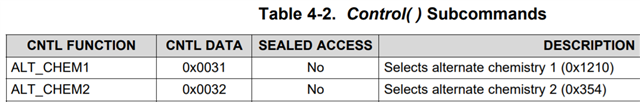

I have programmed the gauge BQ27621-G1 with the following parameters

Design voltage: 3700 [mV]

Design capacity: 1800 [mAh]

Nominal energy: 6660 [mWh]

Maximum taper currente: 180 [0.1 Hr Rate]

Empty voltage; 3000 [mV]

Chemistry ID 1202 (Limited charge voltage is 4.2 [V])

Second battery (available)

Akku Tronics

Model : 103450H-PTLC

Type : Li-polymer battery

Specification : 3.7 [V] / 2000 [mAh]

Li-po battery NCM (Nickel-Cobalt-Manganese)

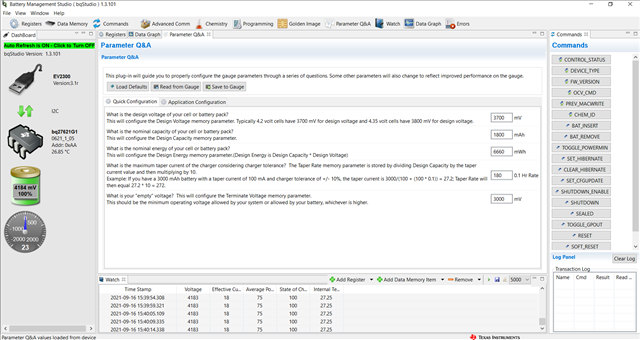

I have programmed the gauge BQ27621-G1 with the following parameters

Design voltage: 3700 [mV]

Design capacity: 2000 [mAh]

Nominal energy: 7400 [mWh]

Maximum taper currente: 180 [0.1 Hr Rate]

Empty voltage; 3000 [mV]

Chemistry ID 1202 (Limited charge voltage is 4.2 [V])

The standard current absorption of my system is around 10mA / 15mA

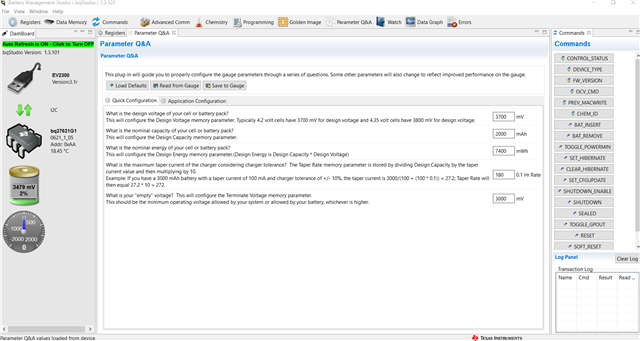

I performed the tests with the standard absorption of the device (10mA / 15mA) and with a resistive load in addition to speed up the 130mA discharge.

The results are equivalent whether I absorb 10mA or absorb 130mA.

The problem is the following:

The reading % of discharge with the 1800mA battery is correct and is a straight line with a constant slope from the beginning of the discharge to the end.

this is perfect,

while:

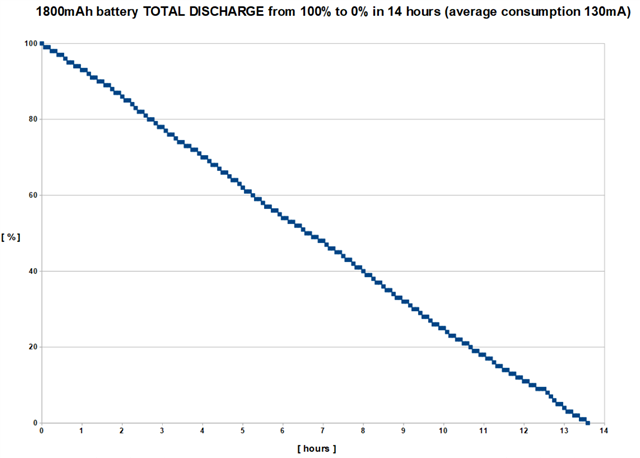

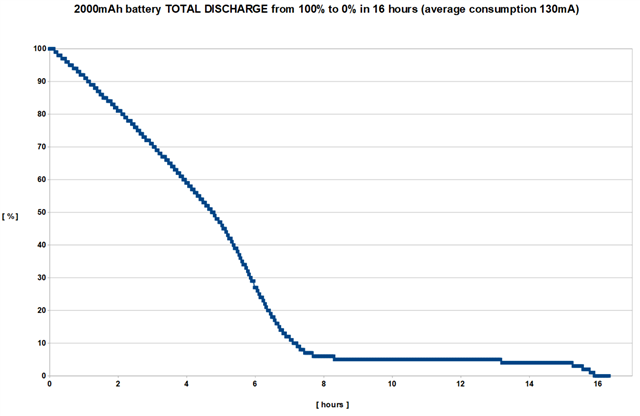

The reading % discharge with the 2000mA battery isn't correct, is a straight line with a constant steep slope initially and at 4% or 5% a plateau is observed which has the same duration as the first phase (constant slope line)

the graph [ % ] / [ hours ] 2000mAh battery TOTAL DISCHARGE from 100% to 0% in 16 hours (average consumption 130mA)

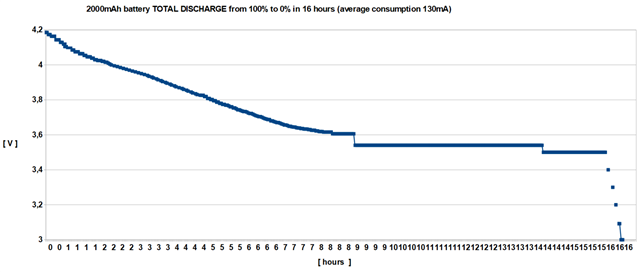

the graph [ V ] / [ hours ] 2000mAh battery TOTAL DISCHARGE from 100% to 0% in 16 hours (average consumption 130mA)

For about 7 hours, the voltage across the battery is 3.54V.

In this phase the battery continues to deliver 130mA at a constant voltage of 3.54V.

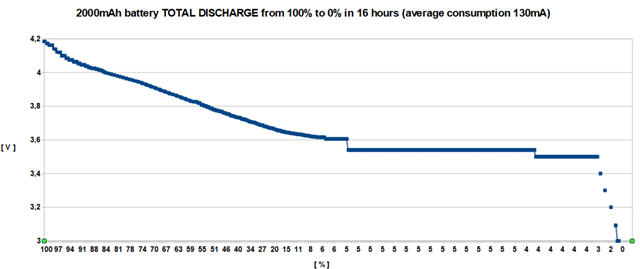

the graph [ V ] / [ % ] 2000mAh battery TOTAL DISCHARGE from 100% to 0% in 16 hours (average consumption 130mA)

For about 7 hours, the voltage across the battery is 3.54V, but the % is about 5% - 4%

it's clear that the problem is in the chemistry of the battery.

The 1800mA battery is characterized correctly with the standard gauge values (except the modified main ones), while the 2000mA battery probably needs to be set in another way.

What do you suggest ?

I found the same results also using the gauge BQ27421YZFR-G1A

Thank you,

kind regards