Hello,

we are using the TPS61080 for PWM dimmed backlight control, but cannot get the current below ~60%. Can an experienced (TI) engineer look at what the problem might be?

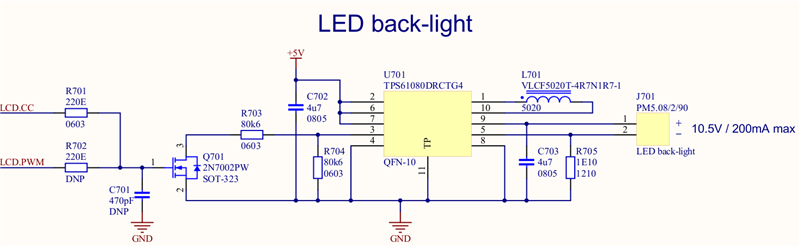

Our backlight has 9 strings of 3 LEDs, 180 mA, we used the datasheet fig. 24 as our reference design, see below.

Our L1 is a TDK VLCF5020T-4R7N1R7-1.

Below a PWM duty cycle of 50% it seems the current goes up again. In fact the 0% duty cycle current through the LEDs equals the current at 100% duty cycle.

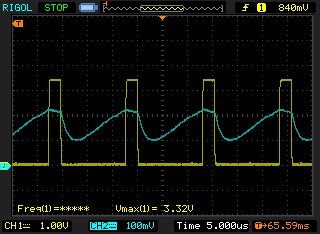

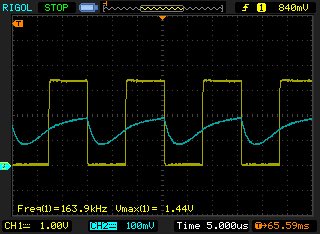

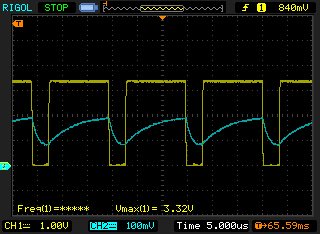

I have included three scope waves on different duty cycles (40, 128 and 200 out of 255).

Yellow is the "PWM Signal" or LCD.CC in our schematics. Blue is the SS signal on the TPS part.

Any insights on why this might happen?

Best regards,

Leon.