Hi.

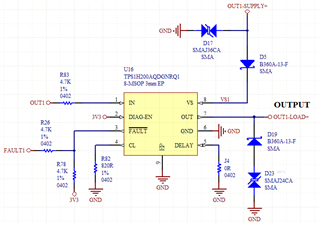

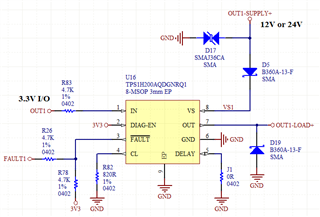

Please could somebody check the schematic below and say if there is something wrong or missing on it? Or if there is any recommendation?

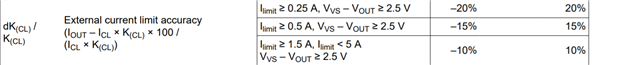

--> CURRENT LIMIT

Worst case... CL pin = 820 Ohms with -1% = 811.8 Ohms

Iout = (0.8 * 2500) / 811.8

Iout = 2.463A

2.463A * 1.1 = 2.71A (1.1 = 10% max tolerance for Iout >= 1.5A)

2.463A * 1.21 = 2.98A (it could be up to 21% tolerance for 3A max)

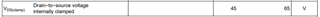

- The diodes B360A are rated for 3A continuos, and 60V.

- The TVS diode SMAJ36CA has a minimum breakdown voltage of 40V.

Questions:

(1) Since my layout is space limited, could I safely remove the 4.7K series resistors, R26 and R83, from pins IN and FAULT? My worry is that in case of damage on the transistor, my MCU coud receive high voltage on it's pins connected to IN and FAULT.

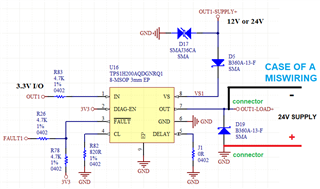

(2) This schematic is for use in a new project of automation module, so lets consider a very wrong installation on field done by the client. The power supplies used in the installations are 24V, so lets consider that the +24V is connected to the GND of the board, and that a GND wire is connected to the load output of the board, at 'OUT1-LOAD+' in the schematic above.

Doing this, the freewheeling diode will be directly polarized and will burn. So I also want to ask if there is another way to protect the circuit from reverse voltage of inductive loads, in a way that if such wrong installations be done, nothing get damaged, but please take into account that my PCB space for this circuit is limited.

Regards,