Hi Team,

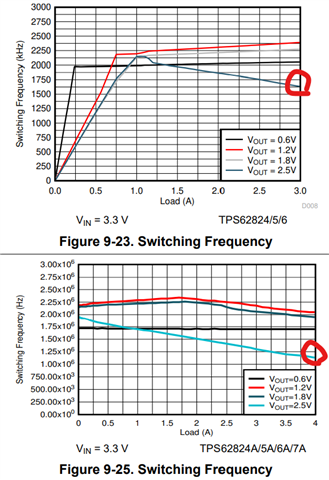

The customer are evaluating of using TPS62827A DC-DC as the alternative candidate for TPS62827 in current product due to shortages.

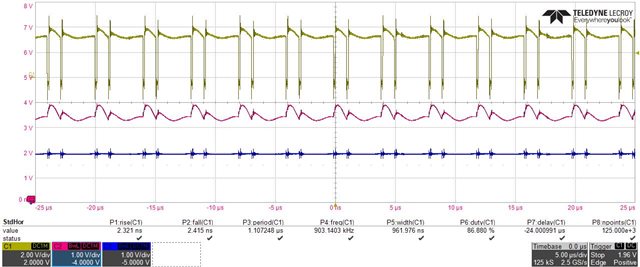

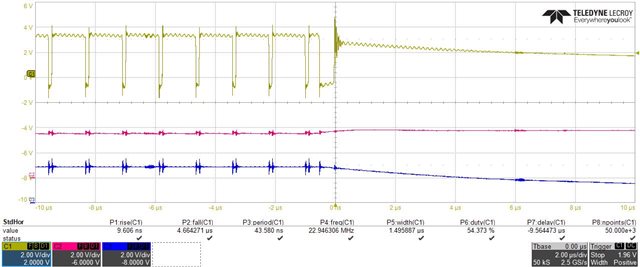

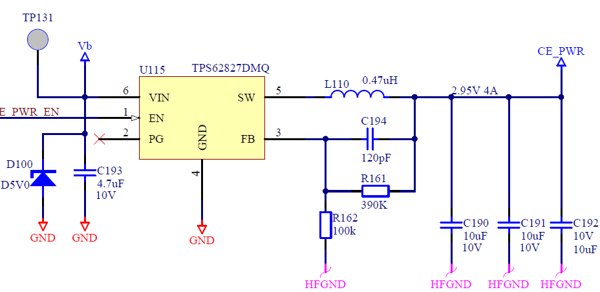

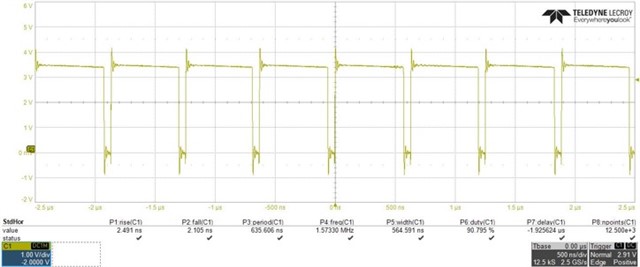

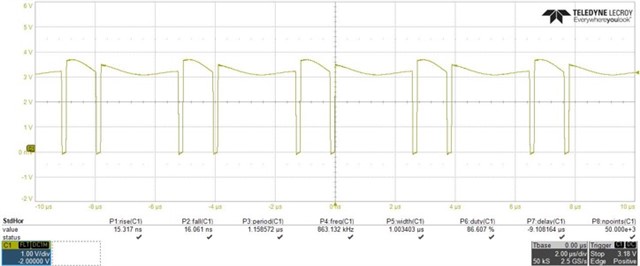

Please reference the switching waveform of these two DC-DC and the schematic as below.

For TPS62827A, the switching waveform seems irregular when we try to operate at 4A and low input voltage of 3.4V. We are not sure if this could lead to instability or you think this is a normal behaviour that we should not worry. Thank you.

TPS62827 Switching waveform (Input 3.4V, output 2.9V, I load = 4A)

TPS62827A Switching waveform (Input 3.4V, output 2.9V, I load = 4A)

Best regards,

Mike