I would like to know the feedback for 2 questions

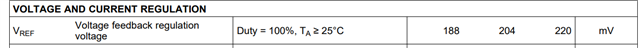

1. Could you please provide feedback voltage tolerance for higher temperature, ex 70 C (please find the attached screenshot - calculated value)

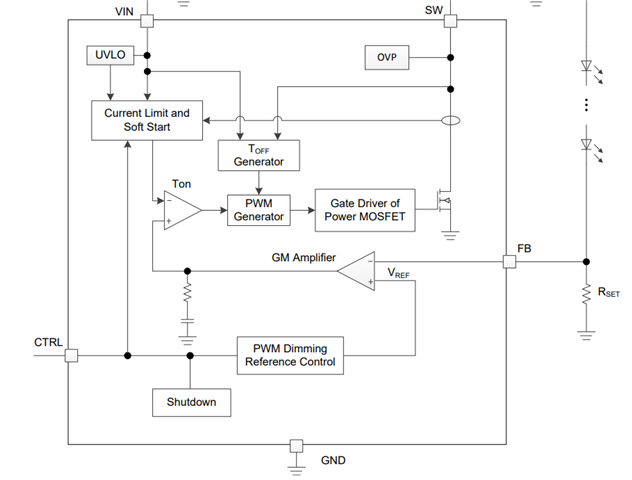

2. As per the datasheet, calculated the led current with feedback voltage for different duty cycle (10,30,50,75,100).

In the design , totally there is 4 led in the string. therefore led current and voltage are measured in testing.( Attached screenshot - Measured value)

For lower duty-cycle, the measured values are out of the calculated range. Could you please able to provide the explanation or reason for this deviation?