Other Parts Discussed in Thread: BQSTUDIO, GPCCHEM

Dear experts,

I am trying to characterize new LiFePO4 cells to be used in a product.

I submitted my charge/discharge data logs via online tool as described here:

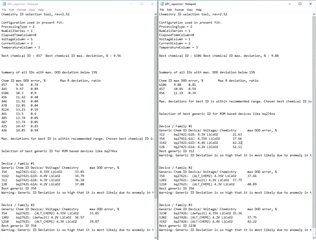

The reports came back with recommended chemical IDs, and the deviations are quite high (9.5-9.9%):

My questions are:

(1) What does this error typically mean for SOC estimation? What kind of SOC accuracy can I expect, and where would the 10% error typically show up (closer to 100% SOC, 0%, or across the entire range)?

Since the gauge (BQ34Z100-G1) has a Coulomb counter, my understanding is that chemical ID only comes into play when the gauge needs to estimate SOC based on the measured voltage - after that, any charge put in or taken out will be taken into account. Please correct me if this is wrong...

(2) In an application where the gauge is active most of the time, can we expect that SOC accuracy will improve over time, despite the initial 10% estimation error due to Chemical ID not perfectly matching the cell? Or are we pretty much guaranteed to always have that 10% error?

(3) Assuming I can't get any better than 10% error in the SOC with these chemical IDs, what would be the next step - do I need to physically submit cells for characterization?

Thank you!