Other Parts Discussed in Thread: TPS548D22

Hi,

We met a question about below:

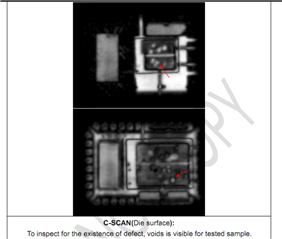

1. C-SCAN(Die surface): To inspect for the existence of defect, voids is visible for tested sample.

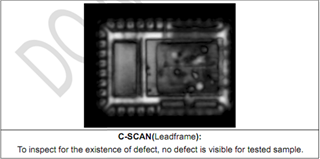

2. C-SCAN(Leadframe): To inspect for the existence of defect, no defect is visible for tested sample.

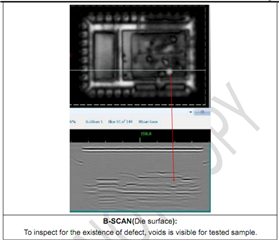

3. B-SCAN(Die surface): To inspect for the existence of defect, voids is visible for tested sample

Will this affect normal use?

Looking forward your reply

Thank you