Other Parts Discussed in Thread: , TPS61169

Dear team,

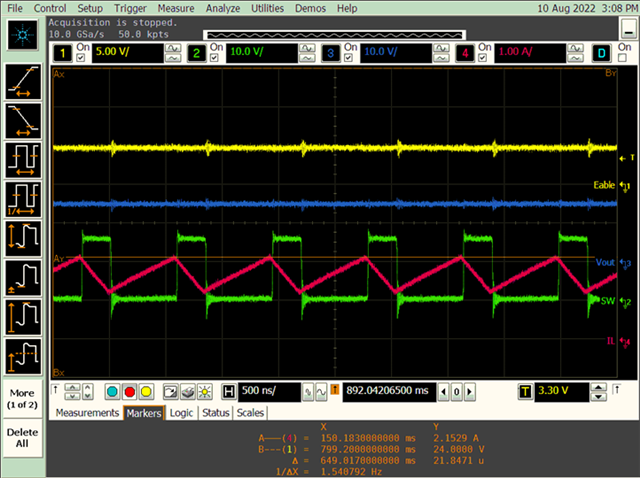

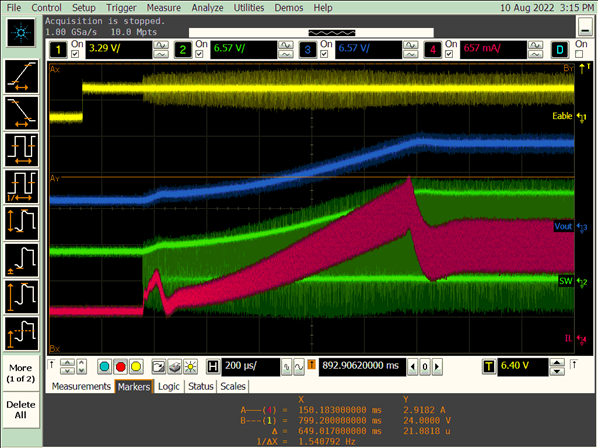

My customer are trying to develop TPS61087 for LED supply. but there is issue of audible noise under PWM operation.

When they input 100% PWM, there is no audible noise but if they input below 100% PWM, there is audible noise.

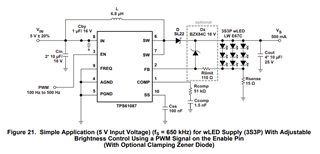

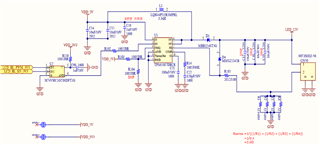

Please review below customer schematic and let me know your opinion regarding how can we debug this issue.

- output capacitor :4 x 10uF

Thank you.