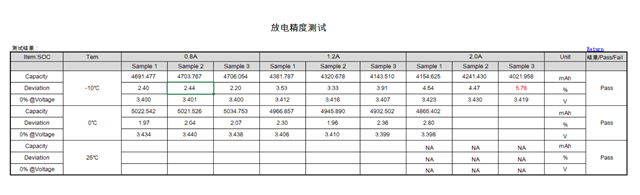

Under the low temperature environment of -10℃, after calibration by GPCRB tool, under the environment of -10℃, the accuracy of RSOC during 2A constant current discharge is poor, more than 5%. The comparison between the log file and the discharge environment is shown in the figure below. Is there any reliable way to optimize RSOC in this situation? Thanks!