Other Parts Discussed in Thread: LM358

Hi Team,

Our customer would like to know how to sense the current ramp of UC3843. Here are the details of his inquiry.

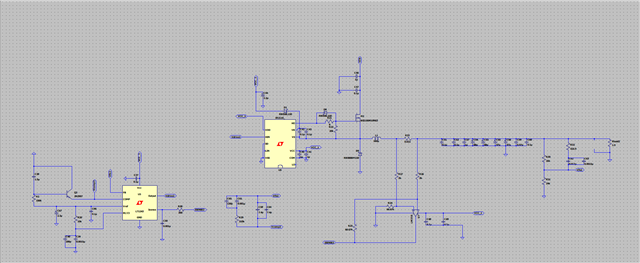

I am using UC3843 to design a buck converter in current mode control. How can I sense the current ramp effectively? I am using a small resistor value in series with the inductor then amplifying it with an opamp.(lm358)

I am getting a discontinuous conduction mode in the inductor yet I designed it for continuous conduction mode. I am using ltspice for simulation

This DCM mode is affecting the voltage ripple I am getting at the load. How can I sense this current for voltage ramp generation?

It is to step down (50V - 95V) input to 5V 3A output

I found the Simplifying Current Sensing application notes in the link below. Can he use the circuit of Figure 2 at page 34 for his application?

Regards,

Danilo