Other Parts Discussed in Thread: BQ25890, GPCCHEM, BQ27Z561

Hi,

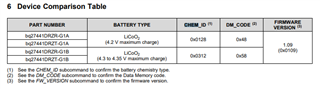

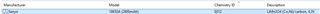

BQ27441-G1b is used in my device.

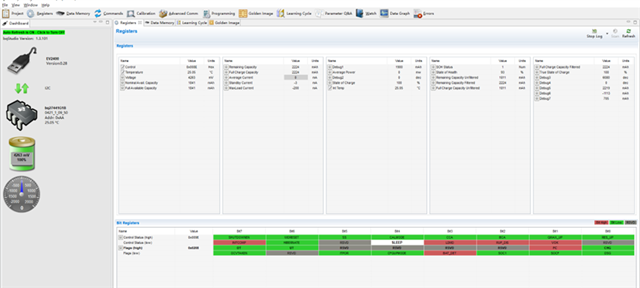

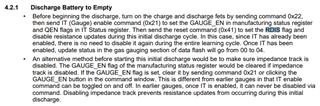

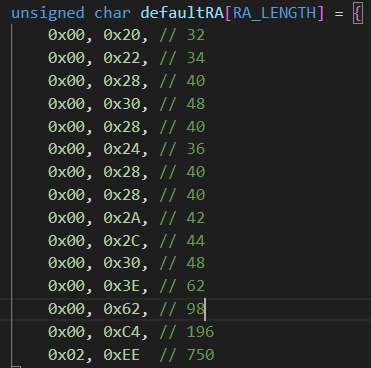

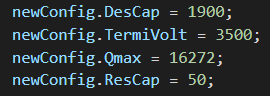

After the battery is plugged in, the following configuration is set to BQ27441 in CONFIG UPDATE MODE.

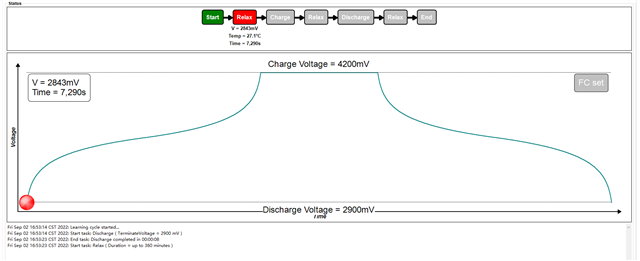

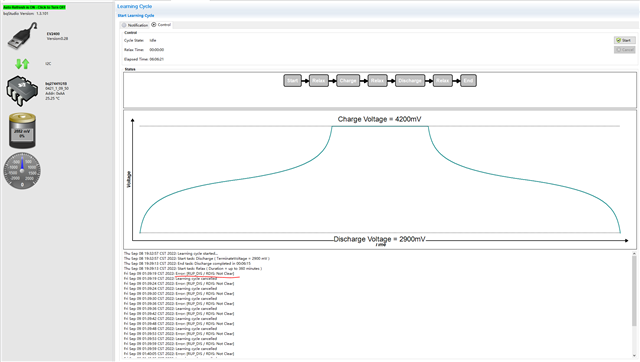

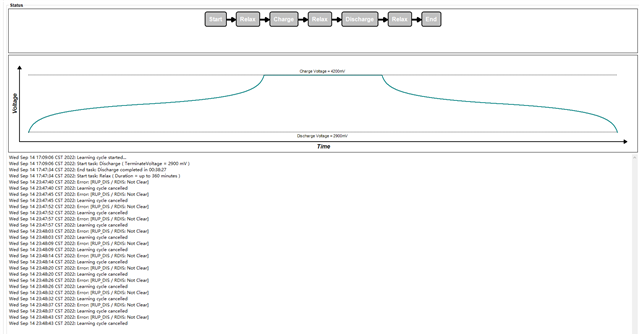

These parameters are learned from following the <bq27441 EVM: System-Side Impedance Track Technology>.

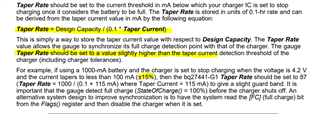

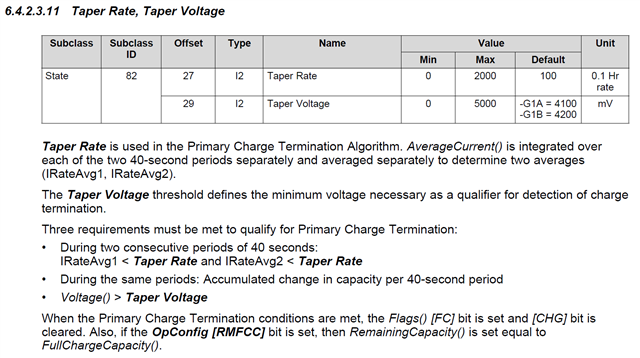

TaperRate = 134.

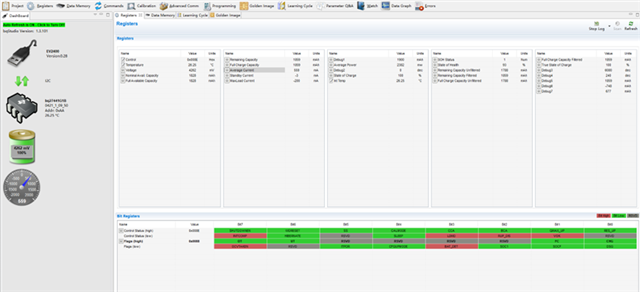

I am sure all the parameters are set correctly into the BQ27441, because I read the registers out and they are right.

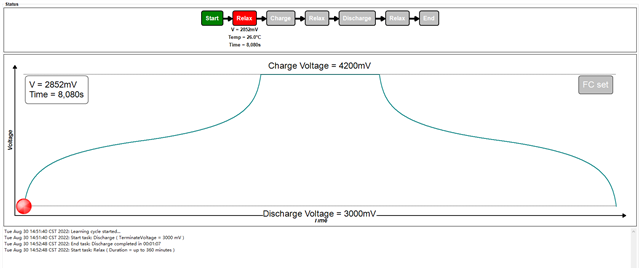

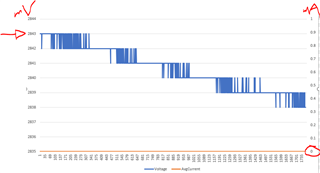

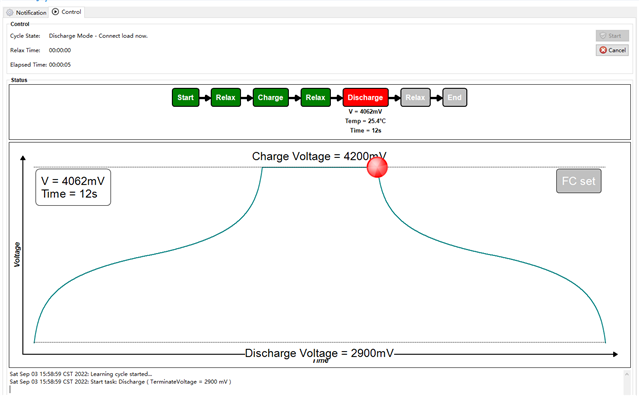

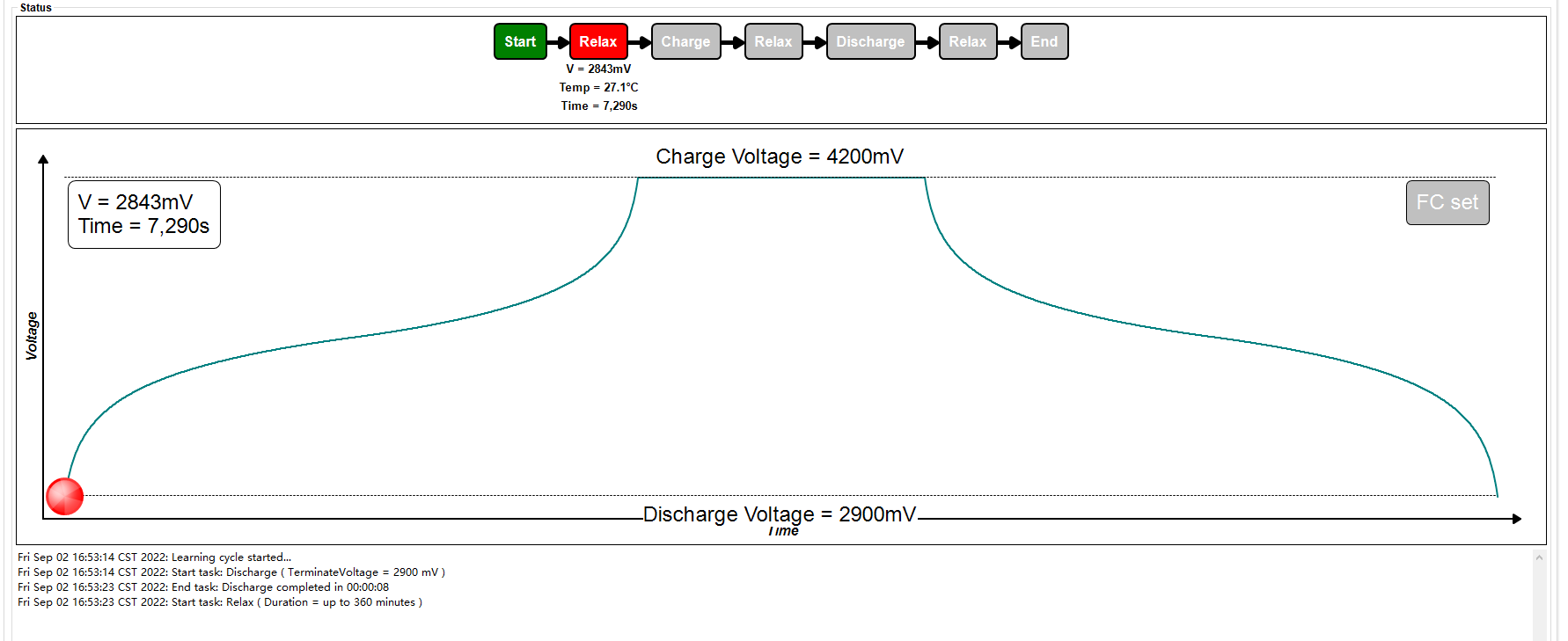

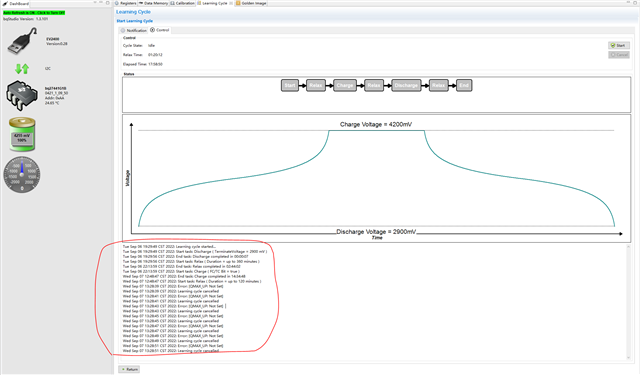

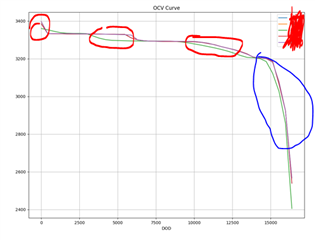

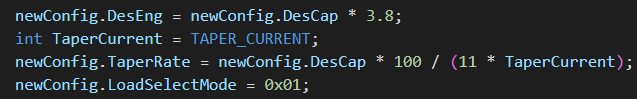

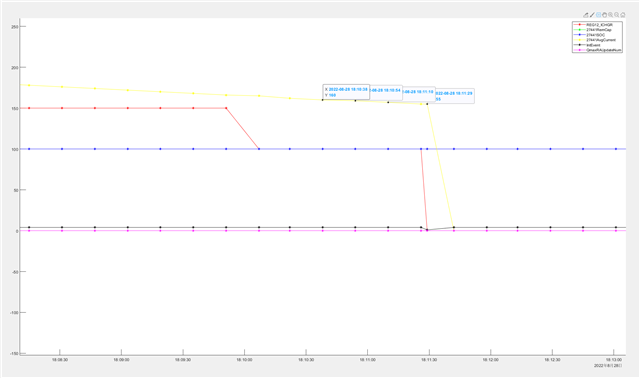

Then, the device is charged and discharged for 3 times:

But I find the Qmax/RA is never updated, and the RemCap is around 1300mAH to 1500mAH, far away from 1900mAH, which is wrong.

Why?

The figure is attached below.

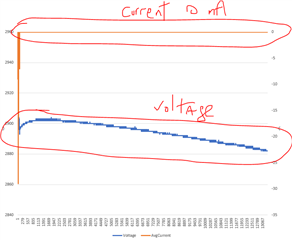

I find that the FC bit is never set to 1 even after the charge termination.

The charging chip is BQ25890, and the terminate current is set to 128mA.

I have read this post:

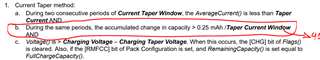

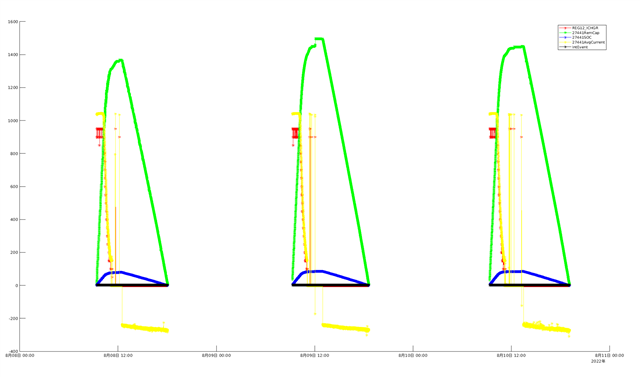

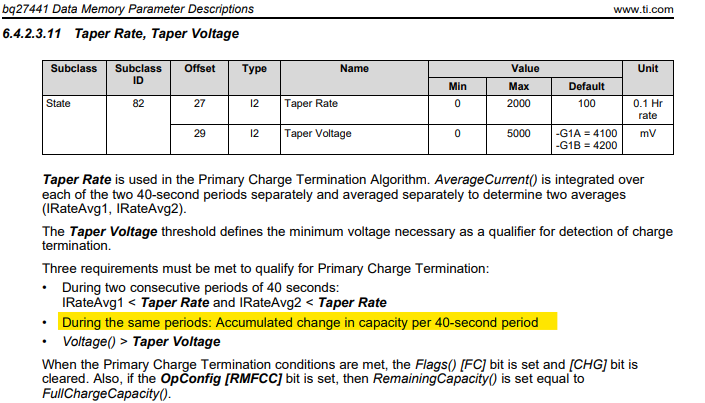

I find the las charging current is 155mA. So it's > Taper Rate(134). So Condition1 and Condition2 cannot be satisfied concurrently.

I'm confused with the Taper Rate.

Taper Rate = 10 * Capacity / TermCurrent =10*1900/128 = 148 Right? Wrong?

But since it's unit is Hr, why compare it with IRateAvg?

What value should I set to Taper Rate in my case, to let FC bit work correctly?

Is it wrong : < Taper Rate and IRateAvg2 < Taper Rate ?

Should it be Taper Current, not Taper Rate?

Thank you.

Frank