Other Parts Discussed in Thread: LM348

Hi,

I am an embedded developer at Thornhill Medical, a company that makes life support devices for military applications.

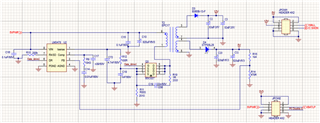

We are currently using the LM3478 IC on of our product as a Flyback power supply (see attached schematic). Recently we built three prototype boards and noticed that out of two of the three boards, the IC U2 (LM3478) is unable to generate the 5V & 12V rails when plugged into the whole system, to be more precise the 5V rail latched at 3V and the 12V rail at 8V. We did a preliminary investigation to ensure that the input voltage going to U2 is stable and found that the input voltage coming from a battery was solid and around 4.0V.

We then tried to replace the IC U2 on the board and after retesting we found out that the problem disappeared and the 5V & 12V rails were available when the board was plugged into the whole system.

Can you please help us identify what would have caused U2 IC to work partially and what can be the potential reason for U2 to get damaged and then work partially?

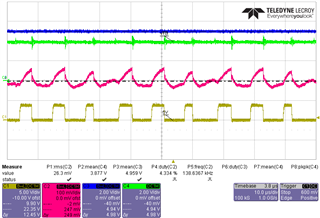

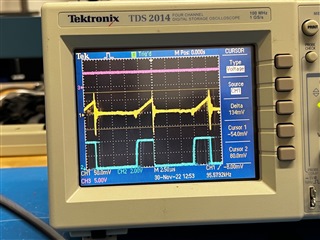

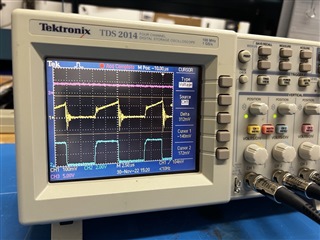

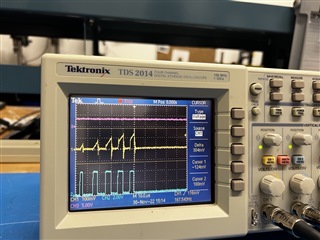

For providing some more details, I am also attaching some oscilloscope screen shots of the IC when it is working under lighter loads

CH1- Gate drive input to mosfet Q3

CH2 - Voltage measured on sense resistor R11

CH3 - 5V rail on the coupled inductor coil 4-5

CH4 - Input voltage coming from battery (5VPWR net in schematic)

We are hitting our deadline in delivering this build and would like to understand the reason for the fallout for U2 before we can proceed to build more units.

Kindly provide us with some guidance into our issue and hoping to hear back from you by end of this week.

Regards,

Nihar Joshi