We have run into problems during PCBA.

The symptoms seem to indicate a cold solder joint with an oxide layer between the solder on the PCB pad and FET metal pad.

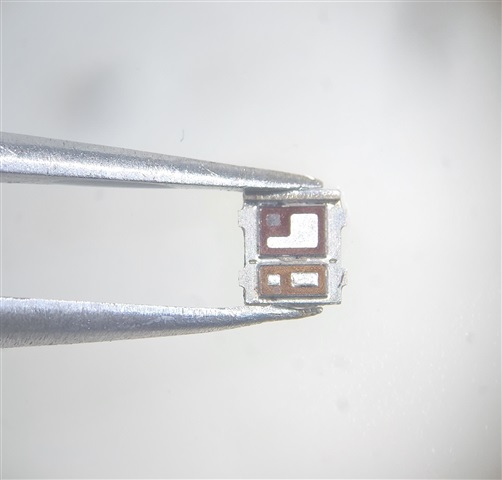

Below is an example of a removed part from assembled board with the gate pad dull and the cause of open after assembly:

The dull pad can be soldered, so there does not seem anything wrong with the actual pad:

These parts come pre-tinned. What would cause the metal pad on the part to become oxidized and form an open during assembly?