Other Parts Discussed in Thread: BQSTUDIO, BQ34Z100

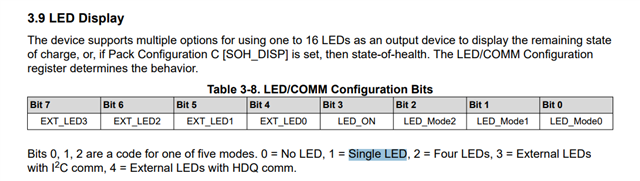

This part has SOC indication that can be multiple LEDs or a single LED. The documented single LED scheme is here (out of SLUSBZ5D pg.39):

" Single LED mode—Upon detecting an A/D value representing 2.5 V on the VEN pin, Single LED mode will

toggle the LED as duty cycle on within a period of 1 s where each 1% of RSOC is a 7.8125-ms high time. So,

for example, 10% RSOC or SOH will have the LED on for 78.1 ms and off for 921.9 ms. 90% RSOC or SOH will

have the LED on for 703.125 ms and off for 296.875 ms. Any value > 90% will display as 90%. "

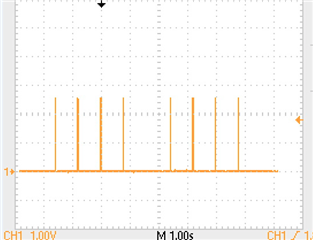

The part does not do this.

We see 0 to 100% duty cycle signal with a period of 800 milliseconds, for 4 cycles, and then no signal for one 800 millisecond "period".

This entire waveform repeats with a total period approaching five seconds. Having designed a low pass filter around the documented specification to create a voltage indicating SOC, we may find it necessary to increase further our time constants and our settling time, if we cannot find a configuration that will follow the part's documentation.

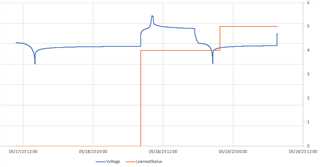

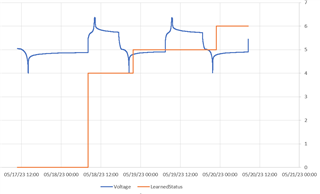

(Blue is voltage, orange is learning status) Here we all see a discharge, a long relax, IT enable and start of charging that changes the learning status to 4. At the end of charge, and the relax that follows, the status does not change to 5 as SLUUBW5A says is expected. After a 5 hour relax, a discharge and another hour wait the status then changes to 5. Again not the expected actions. History has shown us that not until the end of another charge with relax and discharge with relax will there be a status change to 6. We will continue this test to see that repeat.

(Blue is voltage, orange is learning status) Here we all see a discharge, a long relax, IT enable and start of charging that changes the learning status to 4. At the end of charge, and the relax that follows, the status does not change to 5 as SLUUBW5A says is expected. After a 5 hour relax, a discharge and another hour wait the status then changes to 5. Again not the expected actions. History has shown us that not until the end of another charge with relax and discharge with relax will there be a status change to 6. We will continue this test to see that repeat. Status only changes one hour after a discharge..

Status only changes one hour after a discharge.. This (green trace) attempts to show the LED on times for four periods (100%SoC) and off for one period normally, along with one instance of the off time being twice as long as normal with the filtered analog being thrown low (yellow). [ one second per division ]

This (green trace) attempts to show the LED on times for four periods (100%SoC) and off for one period normally, along with one instance of the off time being twice as long as normal with the filtered analog being thrown low (yellow). [ one second per division ]