Other Parts Discussed in Thread: BQ76940, , EV2400, BQSTUDIO

The BQ78350-r1a with a BQ76940 appears to have a bug when the voltage reported is 32768mV

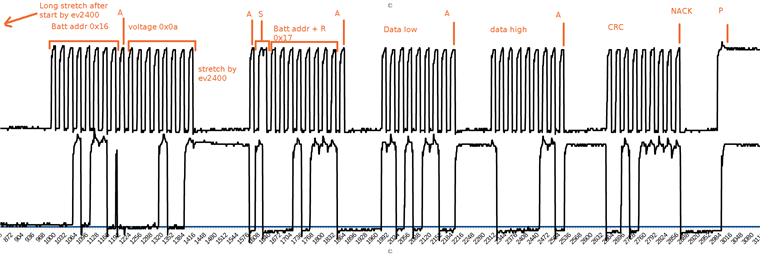

This is confirmed on bit-banging SMBus with a PIC Micro, as well as with the EV2400 and BQ Studio direct to the part.

If the voltage to be reported is exactly 32768, the part will return garbage data.

Any solutions?

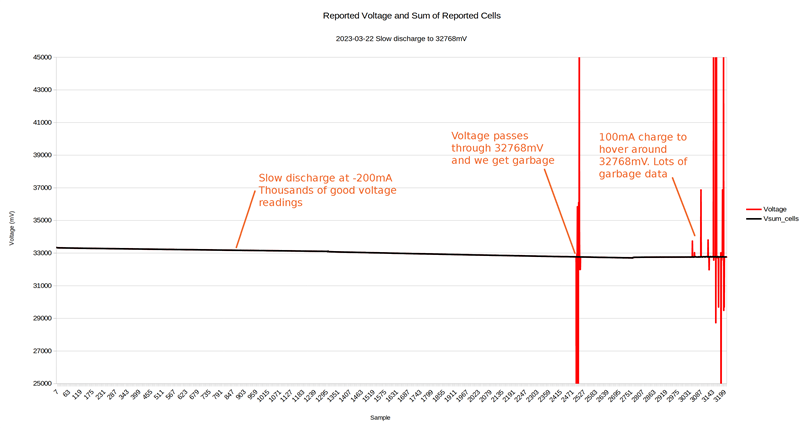

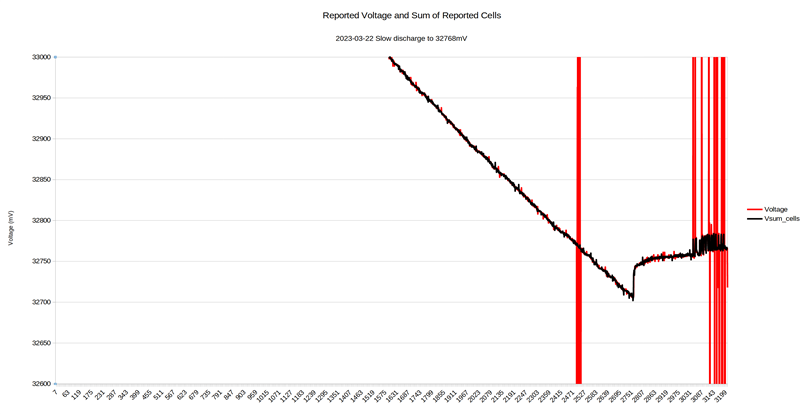

Example data as voltage to the part approaches 32768mV.

Interestingly the part does not "see" these bad voltages, it churns along happily without any error flags.

| Voltage |

| 32749 |

| 32747 |

| 32749 |

| 32749 |

| 32747 |

| 32756 |

| 32740 |

| 32748 |

| 32749 |

| 32738 |

| 32738 |

| 32739 |

| 32754 |

| 32567 |

| 32760 |

| 32765 |

| 31966 |

| 32748 |

| 32765 |

| 32762 |

| 32757 |

| 32754 |

| 32558 |

| 29695 |

| 31985 |

| 48383 |

| 32746 |

| 28858 |

| 45108 |

| 45055 |

| 45104 |

| 35854 |

| 35851 |

| 35852 |

| 33551 |

| 32966 |

| 33740 |

| 33741 |

| 33742 |

| 17345 |

| 17153 |

| 32771 |

| 16432 |

| 16382 |

| 35895 |

| 35896 |

| 32836 |

| 16433 |

| 16433 |

| 17199 |

| 17198 |