Other Parts Discussed in Thread: TPS25947, TPS566242,

Hi all,

I've been working to make a power management board (PMB) that uses the TPS564247 to provide 3.3V, 5V, and 6V. However, during use the TPS564247 regulators manage to keep breaking due to unknown causes and we wanted to get a sanity check on our design to see if there are any errors. For our next iteration we'll be moving to the TPS566242 regulators with TPS25947 e-fuses on each power rail. Here's some more information about out use cases and circuit loads.

- Batteries (6-8.4V, 7.4V Nominal) During usage they never went below 7.5V

- PSU and Battery inputs are never used at the same time

- 3.3V, 5V, 6A loads should never exceed 2.5A max individually, typical is 0.5~1A per regulator

- 3.3V: Microcontroller + low power RF transceivers

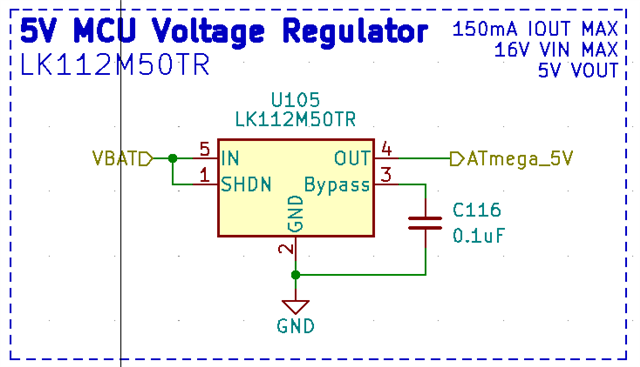

- 5V: Microcontroller + sensors

- 6V: Servo with 2.5A max stall current

- We conformal coat all exposed surfaces

- The enable pin for each regulator is configured to the auto-enable side of the jumper

- Batteries have polarity keyed connectors that prevent reverse polarity situations

As it stands we've worked our way through about 7 regulators due to unknown failures on each voltage rail. The regulators do not release any magic smoke. They simply stop working, except for one specific instance. For example, our system was working nominally we powered it off for a day and then after the next power up the 5V regulator was non-functional. Here are some of our working theories.

- The 6V regulator had too much current draw with our stalling servo or overheated due to extended usage. (We're fairly certain on this one since it emitted smoke once)

- The 5V, 3V3 regulators may have experienced some sort of ESD

- Ripple voltage or current may damage them

- Start up has a too sharp slew rate

Any and all feedback is appreciated. Thank you!