Other Parts Discussed in Thread: ALLIGATOR, TPS565247

Hi, I am attempting to use the TPS565242 to buck from a 12V battery to 5V but experience excessive ripple and noise.

I was wondering if anyone could help me with removing ripple to within 5% at least?

I made a small design on a PCB to test based off the WEBENCH designer which simulates about 12mV of ripple.

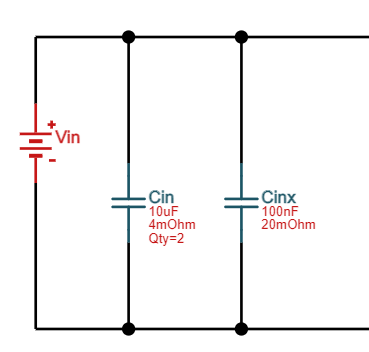

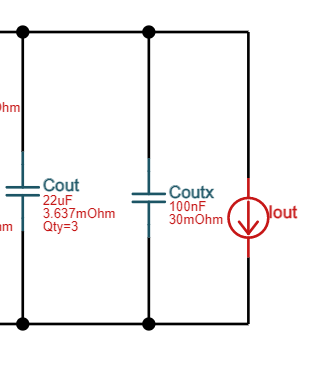

Circuit diagram:

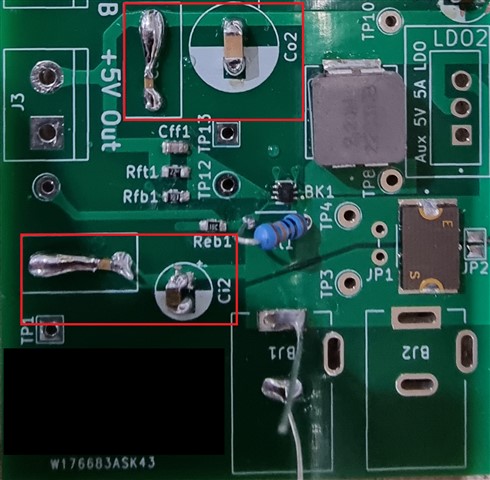

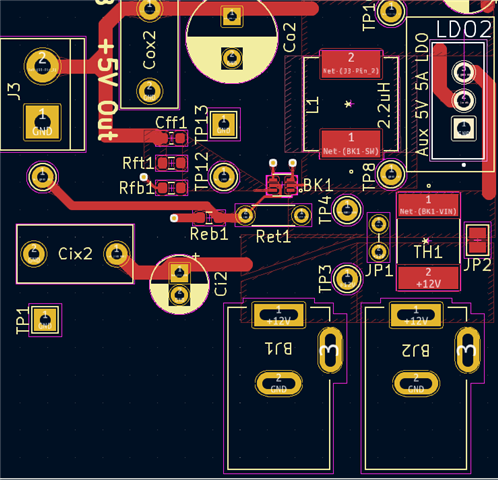

PCB:

I tested the design with a DC lab power supply providing 12V and checked the 5V output with a multimeter.

The multimeter reads ~5.1V but checking with an oscilliscope shows significant ripple and noise.

I attempted to use a few variations of a capacitance multiplier with a LPF RC circuit on a breadboard with some parts I had around but always dropped too much voltage, as I want a 5V output power rail.

The output after the capacitance multiplier to reduce ripple tended to give me close to 3V of power.

I tested with a N MOSFET and NPN BJTs and also tested a Darlington pair.

Any help or feedback would be greatly appreciated.

Apologies if I missed something, it's my first major design on a PCB and my electrical engineering may be a little rough.

Thank you!