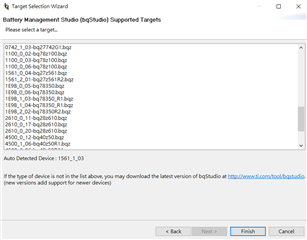

Other Parts Discussed in Thread: BQ27Z561, BQSTUDIO, EV2400, BQ27Z561-R2

Hi team,

I have a few questions wanna figure out:

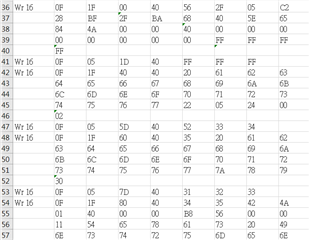

1. In the chapter [Communications] I2C Interface, the figure shows the (b) Quick read R/W bit is sent by slave, isn't it sent by master?

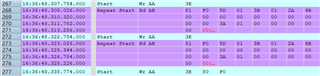

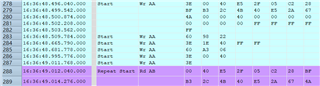

2. I wanna confirm if my understanding is correct, here's an example:

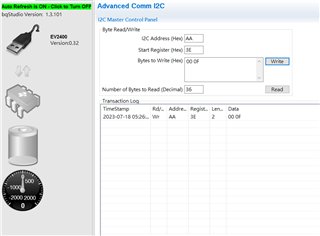

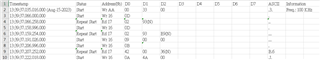

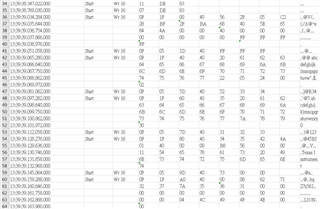

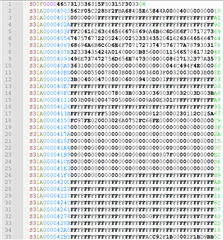

If I want to read the [ChemID], I should write: S 0xAA 0 A 0x3E A 0x06 A 0x00 A Sr 0xAA 1 A 0x3E A 0x06 A 0x00 [A Byte1 A Byte2(return by slave)] N P

am I right?

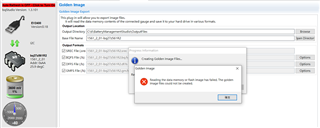

3. Does this kit support [Static Safety DF Signature]?

Thanks.

Josh