At temperatures at or below 0ºC the Impedance Track algorithm will require an extra step to improve the gauging accuracy. If low temperatures are expected in the end application this step will be required for the best results.

The GPCRB tool is used to adjust the temperature compensation factors for resistance estimations, called the Rb table. This improves the Impedance Track gauge's ability to proper determine the Full Charge Capacity (FCC) and Remaining Capacity (RemCap) by applying the correct I-R voltage drop from the simulated load at low temperatures.

To start the process, follow the guide available on the GPCRB tool's webpage: https://www.ti.com/lit/ug/sluubd0/sluubd0.pdf

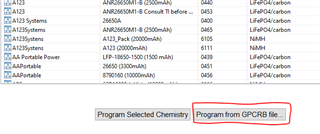

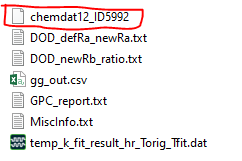

After the steps are completed in the guide linked above, you will receive a report which contains the chemdat file for the specific chemistry ID you are using. Once you have the chemdat file saved, open BQStudio with your gauge EVM powered and connected through the EV2400 adapter, navigate to the chemistry tab from the menu bar. Then select the Program from GPCRB file button.

Now select the chemdat file from the GPCRB report folder and click open.

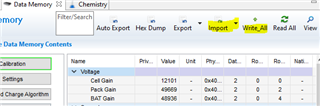

Once BQStudio has stopped loading the chem ID into the gauge, select the data memory tab from the BQStudio menu bar. Now upload the gg_out.csv file from the GPCRB report be selecting Import -> import from file. After this press the Write_All button. Uploading the .gg file updates other temperature compensation factors to improve the thermal modeling of the cell.

Now you have successfully updated the gauge for optimized low temperature performance.

Some common mistakes and what to look out for:

- Ensure the data formatting matches the example in the GPCRB guide, it is best to use the EVM with EV2400 and BQStudio logging since the data requires minimal formatting.

- If possible the procedure should be performed with the cell in the final application enclosure, this will allow the tool to provide the coefficients that are the closest match to the final environment.

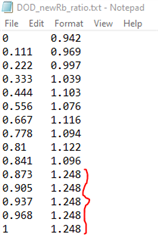

- If your discharge is fairly high for your application even at cold temperatures, the tool may not be able to update the entire temperature compensation (Rb value) table. This is can be verified by looking at the DOD_newRb_ratio.txt file that is part of the GPCRB report. If the ratio values on the right are constant for a majority of the values, the discharge current should be reduced so the lower Rb values can be updated.