Other Parts Discussed in Thread: GPCCEDV, BQSTUDIO, BQ28Z620, BQ40Z50, BQ34Z100, BQ28Z610

Hi,

I have few questions for battery training procedure.

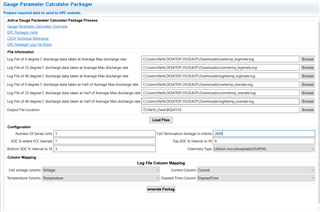

1) How to implement learning cycle for BQ34110 with Li-ION battery? Is there any document for the same?

2) BQ34110 required chem ID procedure for learning cycle?

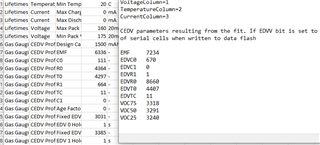

3) Which parameters i need to set in data memory before starting learning cycle? Can you provide me the list for the same.

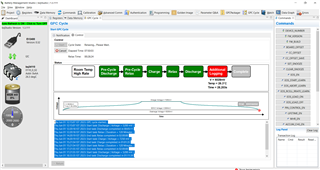

I am using 2 batteries in series connection and battery management studio to implement learning cycle.

Thanks,

Parth