Other Parts Discussed in Thread: BQ25720, BQ25731, BQ25750

Hi,

In our project we need to use a charging solution,please help provide a suggested IC

First, I will list some of our requirements for charging equipment.

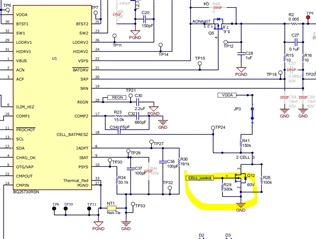

A DC adapter will be used as the input power on our system, the specification is 9 volts/10 amps.

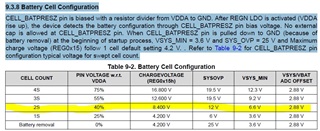

Our battery packs use Li-Polymer cells with specifications from 6 to 8.4 volts/10 amps, configured as 2S (2 batteries in series).

There are three different applications in the charging system according to customer needs.

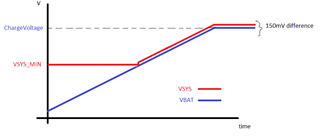

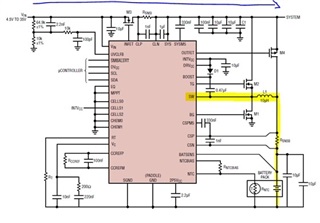

- Case 1 (cost-saving version): Using a DC adapter as the input power supply and removing the Ll-Polymer battery. The output power specification requires is ~9V/10A.(keep the charging IC on the PCBA).

- Case 2: Using a Ll-Polymer battery as the input power supply and removing the DC transformer, , The output power specification requires is ~6 to 8.4 volts/10 amps.

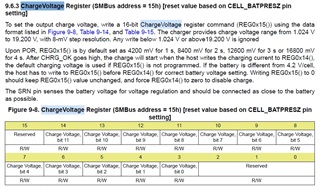

- Case 3: The DC adapter is used as the input power, and the Ll-Polymer battery is retained. The output power specification requires is ~9 volts/7 amps, and 3 amps are provided to charge the battery.

Our questions :

- Can you help confirm that BQ25720 or BQ25730 meets our needs? Or have other suggested ICs.

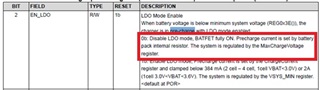

- Can you help confirm that BQ25720 or BQ25730 have dynamically adjust the VSYS setting value? (For example: VIN=9V,VSYS=5V or 6V or 7V…)

- What is the difference between BQ25720 and BQ25730?