Other Parts Discussed in Thread: LM74930, LM74800-Q1, TPS4811-Q1, LM7480,

Hi!

I have pretty interesting task, not sure if possible.

That is my goal for now - get weight/size estimation.

Task is to design power distribution board with power supply ORing, total weight should be less 500g.Product is VTOL (drone)

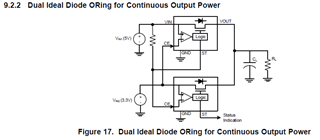

ORing should be on 2 power supplies, one is 50V60A, second is 12s battery (max52V) 300A.

350A is expected during half minute, 200A expected during 1 minute, usually 50A.

Load is inductive - ESC + motors.

I also need to measure current. I think using shunt for 350A is not best solution, better use Rdson or hall effect based sensor.

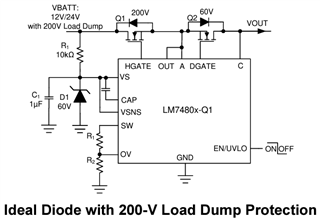

I assume the best fit is LM74930.

I found out that best MOSFETs now for 60V capable to hold up to 40A continuous in ambient (no radiator)

NVMTS0D7N06CL looks nice

I think using more mosfets in parallel will take less weight, than applying radiator.

So for 50V60A

2*Q1+2*Q2 + LM74930

For 300A

8*Q1+8*Q2 + LM74930

Back mosfets I think will help me in case of BackEMF problems from inductive loads.

What do you think? I understand, MOSFETs in parallel have higher charge and so with the same current from driver it will switch slowly, but I think for this application it is ok.

For current sense I think to use hall based sensor, and for CSP-CSN I can provide voltage output throw resistive devider.

Will this work? I didn,t see problems from internal schematics for current sense block

Ye, looks crazy, but give me honest feedback

Thanks.