Tool/software:

Hello,

we experience a strange behavior where the TPS23861 does not perform a classification event, if multiple devices are attached. The general error path looks like this.

The TPS is working in Semi Auto mode.

Attach a PoE sink to “Port 1” of the TPS – Sink will be powered.

Attach another PoE sink to "Port 2" of the TPS – Sink will be powered.

Attach a 3rd PoE sink to “Port 3” of the TPS – Sink will not be powered.

Attach a 4th PoE sink to “Port 4” of the TPS – 3rd and 4th sink will be powered.

All PoE sinks are of the same type and are Class 2 devices.

There are other combinations that lead or resolve the error as well. But the depicted case is the most reliable one. Our measurements show that the TPS is not performing a classification event on Port 3 in this case. Instead, the 4-quadrant measurement is repeated as a loop. We also do not see any changes to the chip registers happening while the PoE sink device remains unpowered.

To make the error more complex. It does not always happen. There are some PoE sinks that seem to trigger the error, while other identical PoE sink combinations works flawlessly. The error does not occur in Auto mode. But due to software restrictions we must use the Semi Auto Mode. All devices, as well as our TPS23861 hub have been tested for 802.3af compliance via dedicated compliance testing equipment.

When we checked the PoE signals on the sink, we did not see any difference between good and bad cases. The only irregularity we see is a different behavior in regard of the number of classification events. While the datasheets stated that in Semi-Auto mode a single classification event should be performed for Class 0-3 devices, we see two events like it should be the case for class 4 devices. But this seems to happen regardless of the used PoE sink. We have seen this behavior for multiple different vendors and chipsets, while all the used PoE sinks where class 2 devices.

Therefore, it seems that we still have a problem with our implementation. Could you elaborate what exactly happens during the 4-quadrant detection event? What timings, voltage levels and requirements are need by the TPS to trigger a classification event?

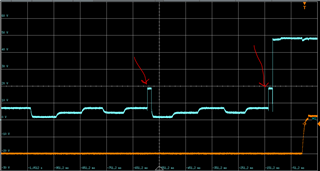

To give you some additional insight, here some of our measurement results. Blue is the PoE voltage at the sink, behind the full bridge rectifier didoes. Orange the output voltage of the PD chipset in the sink device.

First a "regular" power up event. As you can see, the classifcation event is performed 2 times, instead of a single event.

Then for comparison the same device in auto mode, where only a single classification event is seen.

An the last measurement shows the error case where no classification is happening at all. Green and yellow can be ignored, as those are diffential signals used for the blue math function curve.

Yours faithfully

Christopher