Tool/software:

Hi,

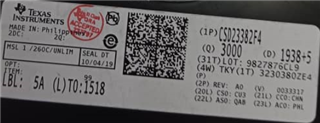

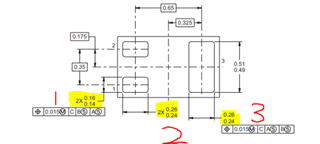

I’m writing here to bring the issue of dimension NG we are having now and seek for advice from Texas Instrument team. For your information, our team found dimension NG for three parts after measured with two samples. The machine we used to measure dimension is Pricis-VMG450 and its video measuring software, Measuremind. Through the software, we usually draw two lines and measure the gap between them to find the dimension. Please refer to the picture and table below for the details of measurement.

|

Part |

Nominal (mm) |

Tolerance |

Dimension (mm) |

Measured dimension (Sample 1) (mm) |

Measured dimension (Sample 2) (mm) |

|

|

LSL |

USL |

|||||

|

1 |

0.15 |

0.01 |

0.14 |

0.16 |

0.1588 |

0.1609 (NG) |

|

2 |

0.25 |

0.01 |

0.24 |

0.26 |

0.2615 (NG) |

0.2662 (NG) |

|

3 |

0.25 |

0.01 |

0.24 |

0.26 |

0.2522 |

0.2627 (NG) |

We hope to get support from Texas Instrument team and get advice on the questions below:

- Does these dimension NG consider as normal or abnormal?

- Would these dimension NG affecting the function of the component?

- Do we measure with the correct method? Please correct us if we are using the wrong method to measure dimension.

Thanks and best regards,

Cheah