Other Parts Discussed in Thread: BQ51051B, , EV2400, BQSTUDIO

Tool/software:

Hi TI team,

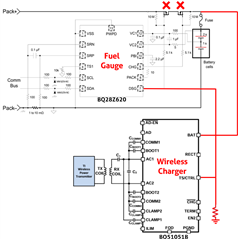

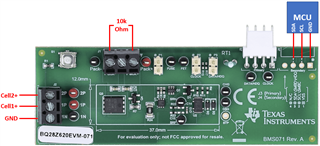

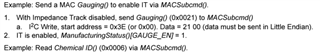

we are using the BQ51051B wireless charger IC on a design where we were measuring the temperature in a custom way to only allow charging on a temperature interval. Now, we would like to substitute this custom circuitry for a BQ28Z640 fuel gauge to control temperature but also getting some SoC and SoH parameters.

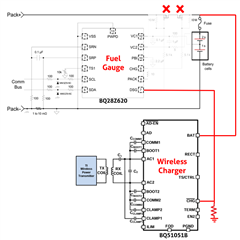

We have been reviewing the recommended fuel gauge schematics, and all of them points to use a back to back MOSFET configuration to unplug the power line in case any alarm is triggered, by driving CHG and DSG pins. We would like to avoid the use of these two extra components and to connect any of these CHG and DSG directly to the CHG pin of the BQ51051B battery charger so that the charghing is stopped.

Another option could be to use the wireless charger AD pin to drive the charging operation. During the docs review, we ar only clear that, wireless charger CHG should be pull-down driven but not many information regarding the fuel gauge CHG/DSG internal schematic, so we do not know if these configuration proposed on the image could be possible.

Any information you could provided, will be welcome.

Regards,

eesy innovation.